Complete sludge dewatering system

The centrifugal sludge dewatering and drying equipment produced by our company, usually used for sludge thickening and dewatering, is mainly composed of a LW series decanter centrifuge (or screw press), a full-automatic flocculant preparation and dosing device, a sludge crushing and cutting machine, a sludge feed pump, a dosing pump, a shaftless screw conveyor, a flowmeter, a control valve and a complete full-automatic control system. Characterized by advanced structure, reasonable configuration, high degree of automation, continuous airtight operation, safe and reliable operation, etc., it is applicable to the treatment of municipal sewage, rural sewage, hospital sewage, etc. as well as various types of industrial sewage.

- Overview

- Related Products

System Working Principle

The mixed sludge from the municipal sewage that has undergone primary sedimentation and secondary sedimentation normally has a solid content of about 2-3%. It is then dewatered and thickened with a decanter centrifuge (or belt filter, screw press) and the discharged sludge has a moisture content of about 80-85%. Later, the sludge enters the sludge low-temperature heat pump heating and dehumidification equipment for dehumidification and drying, and the moisture content of the treated sludge drops to about 30%. Thus, the harmless treatments of the sludge, such as incineration or utilization after pyrolysis, can be conducted.

Treatment Process

①Solid content of mixed sludge: 2-3%

②10% added when PAM concentration is 0.1-0.3%

③Moisture content of cake after sedimentation and thickening: 80%

④Paved to mesh belt after pretreatment by strip cutting machine

⑤Moisture content of cake after cold drying: 10-30%

⑥Sludge post-treatment: incineration, building materials, composting and landfill

Scope of Application

For a long time, due to the stress on water treatment and the ignorance of sludge treatment, at present, only about 30% of the sludge is safely disposed of. Large amounts of wet sludge are transported out randomly, simply landfilled or piled up. Exposed to the air, the sludge is prone to stink and attract mosquitoes, and cannot be used as fertilizer.

The requirements of the Action Plan for Prevention and Treatment of Water Pollution and other relevant national laws and regulations for sludge treatment and disposal have continued to increase in recent years. Therefore, the sludge shall further undergo stable and harmless resource treatment and disposal, and the moisture content of sludge for landfill, incineration, land use, etc. shall be lower than 60%.

PAM Solution Automatic Dosing Device

JY series PAM solution automatic dosing device, mainly composed of an automatic dry powder dosing system, an automatic quantitative water injection device, a vortex prewetting device, a liquid level monitoring device, a stirring device, pipelines, valves, etc., is a system device integrating dry powder storage, feeding, wetting, dissolution and curing. The system under full-automatic control can be used for batch and continuous preparation of high-molecular polymer solution. It is widely used in sewage treatment, drinking water purification, industrial wastewater treatment, papermaking, ore smelting, etc.

Working Principle

PAM powder passes through a high-efficiency vortex wetting device, is then mixed with water, fully stirred and dissolved into a PAM solution with a concentration of 0.1~0.5%. Later, the solution is cured and put in the storage tank for standby application.

The curing time of the prepared solution depends on the nature of the agent, the required flow rate of the process and the effective volume of the device, and generally, the dissolution and curing time of the solution shall reach 45-60min to ensure the dissolution and curing effect of the solution and the full curing of the agent.

Feed water according to the set flow rate and at the same time, automatically add quantitative dry powder; wet the power in the prewetting device, put it in the dissolution tank for mixing and dissolution; when the liquid level reaches the overflow height, put it in the curing tank for stirring and curing and at the same time, stir the solution in the dissolution tank; when the liquid level reaches the overflow height, put it in the storage tank for storage and standby application; after the curing, when the solution in the storage tank rises to the high liquid level, use the prepared PAM solution. After the first preparation, the device supplies solution required for the process while preparing a new solution, which can meet the needs of continuous operation for 24 hours.

Sludge Dewatering System – Screw Press

Scope of Application

Screw press is widely used for sludge dewatering in such industries as municipal sewage, food, beverage, slaughter and breeding, printing and dyeing, papermaking, leather and pharmaceuticals.

Structure and Operating Principle

The separation unit of the screw press is composed of a fixing ring and a floating ring which are stacked on each other with a small gap in between. The spiral shaft passes through it and rotates to drive the floating ring to move circumferentially. The water in the flocculated mud pie is filtered out through the gap between the fixing ring and the floating ring, and the floating ring moves circumferentially to prevent blockage. The gap between the fixing ring and the floating ring becomes smaller along the direction of the cake outlet from the thickening zone to the dewatering zone, and forced dewatering is achieved under the back pressure formed by the back pressure plate of the sludge outlet.

The sludge is sent by the sludge transfer pump to the sludge inlet, and the flocculant is metered and sent to the flocculation mixing tank, where the sludge is fully stirred with the flocculant and flocculated. After being flocculated into large floccules, the sludge enters in the spiral separation unit from the spiral sludge inlet. The floccules in the spiral separation unit are under gravity thickening while moving towards the dewatering zone under the action of the spiral. The gap between the floating ring and the fixing ring in the dewatering zone is narrowed, and the sludge is further pressurized and dewatered under the action of the back pressure plate, and is discharged from the sludge outlet as cake.

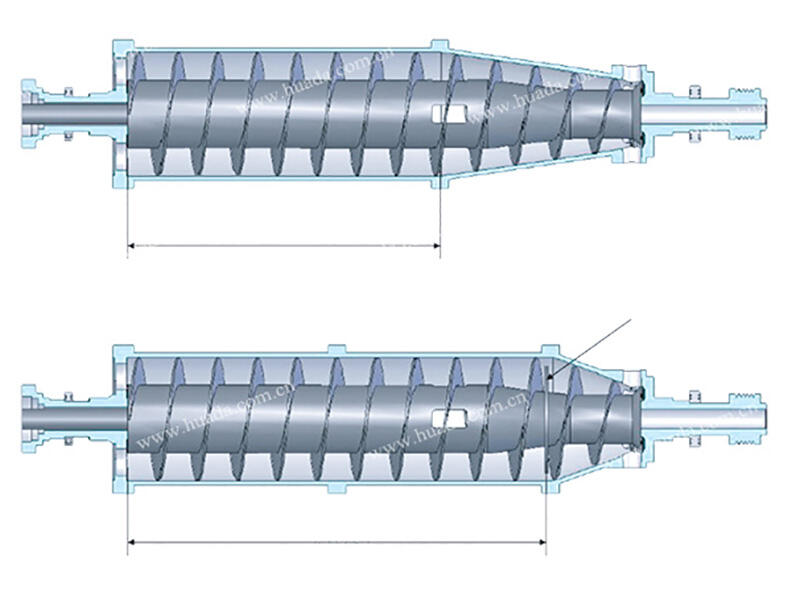

LW Sludge Dewatering - Dedicated Decanter Centrifuge

The centrifuge is composed of a bowl rotating at high speed, a scroll that runs in the same direction as the bowl and has a certain speed difference, as well as a differential, a base, a feeding and discharging system, etc. The sludge and flocculant enter the bowl after being mixed in a specially designed feeding chamber. Under the action of centrifugal force, the flocculated particles are quickly separated and sedimented in the sedimentation zone, and the clarified liquid is discharged through the overflow hole at the end of the bowl. The sedimented solids, after being squeezed and dewatered by the BD baffle, is pushed by the scroll conveyor to the drying section of the bowl for further compression, and then discharged through the slag outlet. The dewatering time of the solids in the bowl can be controlled by adjusting the differential speed between the scroll and the bowl.

Main Features

Bowl speed: The bowl is designed with high speed and large separation factor, which can effectively clarify tiny particles with size ≥5μm.

Length-diameter ratio: The actual effective length-diameter ratio of the bowl is ≥4, and the sedimentation distance is long, which increases the clarification and dewatering time of the sludge in the bowl.

BD baffle: There is a circular baffle between the scroll sedimentation section and drying section, which squeezes the sludge in the settling section into the drying section, so that the moisture content of the sludge is lower; meanwhile, it cuts off the connection between the sludge and the clarified liquid. The depth of the liquid pool can be greater than the slag outlet, and the deeper the liquid pool is and the longer the process takes, the better the clarification effect is.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ