Sludge low-temperature heat pump drying system

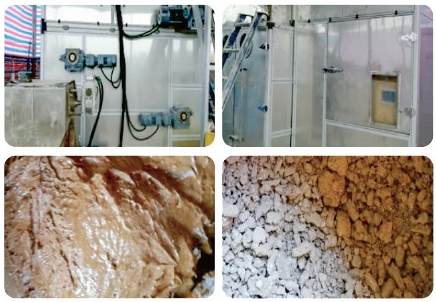

SDDR sludge low-temperature heat pump heating and dehumidification equipment is sludge deep dewatering equipment, which can effectively treat the sludge with a moisture content of 85% or lower to a minimum of 10%. It is widely used in the treatment of municipal sludge, industrial sludge and solid waste, hazardous waste and other sludge. The equipment is composed of a low-temperature heat pump heater & dehumidifier, dewatered sludge pretreatment equipment and mesh belt transmission equipment.

- Overview

- Related Products

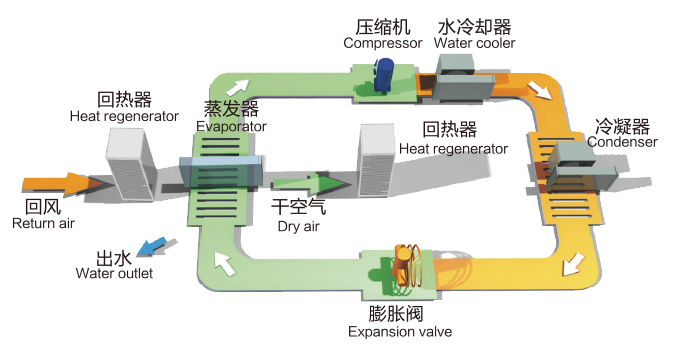

Working Principle

Inject dry air into the airtight drying chamber, and take out the moisture in the sludge through humidity exchange, then use the evaporator to condense and remove the moisture in the air, and at the same time, take advantage of the heat pump principle to recover the latent heat of moisture condensation, use it to heat the dry air and blow the air back into the drying chamber. Since the heat recovery technology is adopted, no waste heat is emitted in the airtight drying mode.

Technical Advantages

Modular design

-Skid-mounted or vehicle-mounted design makes it unnecessary to conduct on-site assembly construction.

-Heat pump and fan are integrated, avoiding pollution, easy to disassemble and assemble.

-Tail gas treatment module is integrated, so no separate skid is required.

Eco-friendly

-There is no chemical addition, so the subsequent disposal of sludge is not affected.

-The equipment runs in an airtight manner at low temperature, and the hot air is recycled and reused, which is environmentally friendly.

-The tail gas treatment device is selectively assembled at the solid discharge port, preventing bad smell at the drying site.

-New refrigerant ODP=0, GWP value is extremely low, working noise <55 decibels.

Energy conservation

-Energy recovery rate is close to 100%, and 2.5~4.2kg sludge can be dewatered with just 1 kilowatt-hour of electricity.

-Equipment can be customized according to customer requirements to provide the best solution for energy conservation and consumption reduction.

Reliability

-The equipment runs at low speed and uses corrosion-resistant materials.

-Mobile terminal monitoring of the equipment can be realized with just one key.

It has software setting protection, failure prediction, early warning and shutdown functions.

Parameters

|

Items |

SDDR1500 |

SDDR3000 |

SDDR4500 |

SDDR6000 |

|

Wet sludge treatment capacity(80%-40%) |

2T |

4T |

6T |

7.5T |

|

Standard water intake(24h) |

1500kg |

3000kg |

4500kg |

6000kg |

|

Operating power |

16-20kw |

32-40kw |

48-60kw |

64-80kw |

|

Drying temperature |

50-65°C(retum air)/ 65-85°C (supply air) |

|||

|

Moisture content of dry material |

Variable frequency regulation: 10% at a minimum |

|||

|

Number of compressors |

1 set |

2 sets |

3 sets |

4 sets |

|

Dimension (LxWxH)(mm) |

3000*2950*3000 |

4500*2950*3000 |

5100*3300**3000 |

6600*3300*3000 |

|

Spiral feeding elevator |

Optional |

Optional |

Optional |

Optional |

|

Secondary strip cutting machine |

Optional |

Optional |

Optional |

Optional |

|

Tail gas deodorization atthe solid discharge port |

Optional |

Optional |

Optional |

Optional |

|

Sludge feed hopper |

Optional |

Optional |

Optional |

Optional |

|

Weight |

3T |

5T |

6T |

7T |

|

The processing capacity of the equipment can be customized according to customer needs. We have larger models, please feel free to inquire |

||||

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ