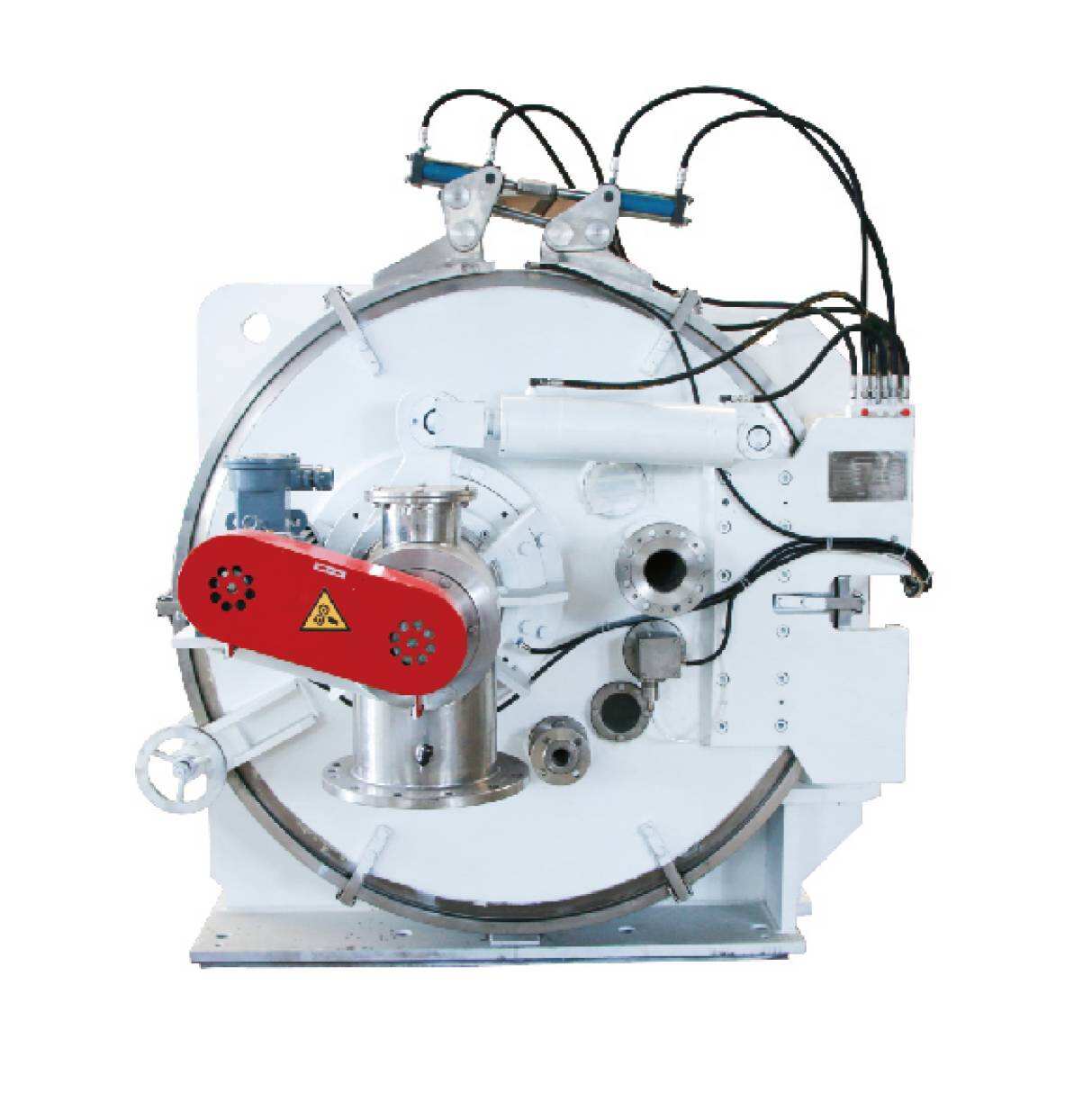

GK Peeler Centrifuge

GK horizontal centrifuge is a type of automatic filtration centrifuge featuring continuous running, intermittent operation and high-speed peeling, which is able to complete feeding, separation, washing, dehydration, discharging, back-blowing and other processes at full speed, and therefore is commonly applied to the washing and solid-liquid separation of suspension medium containing solid particles. With high separation factor, short single circulation duration and large handling capacity, relatively dry residues after filtration can be obtained and ideal washing effect can be ensured.

- Overview

- Related Products

GK Peeler Centrifuge has high performance in separating suspensions with the cake density of 0.8~2.5, particle size of 0.05mm~1mm and solid concentration of 15%~80%.

It has been widely applied in the chemical, food, pharmaceutical, light industry and other industries for separating such materials as sodium bicarbonate, caustic soda, starch, boric acid, ammonium sulfide, sulfuric acid, sodium sulfate, ferrous sulfate, calcium phosphate, polyvinyl chloride, sodium chloride, and potassium chloride.

Product Configuration

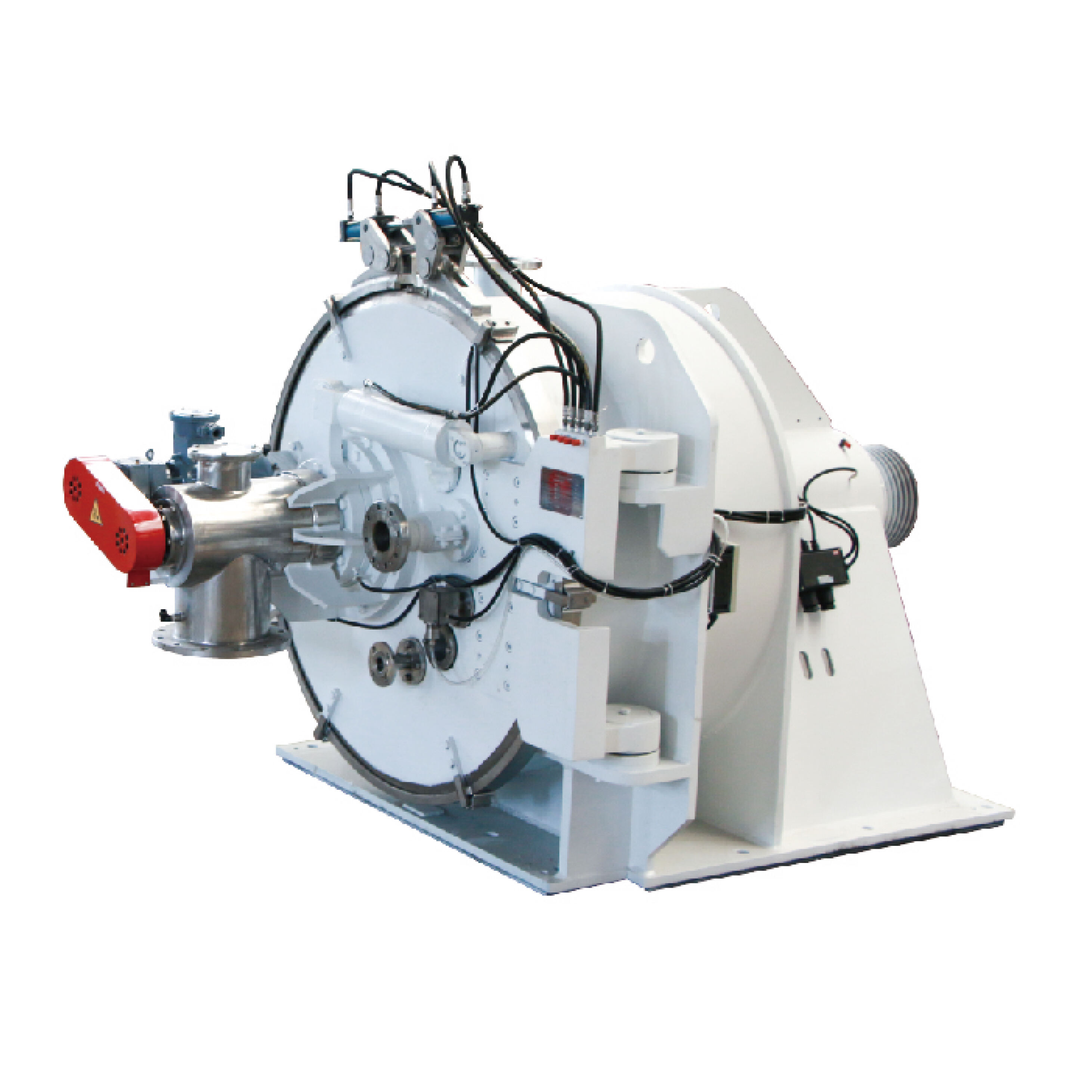

Control mode: PLC control, with touch panel and human-machine interface and supporting electric-hydraulic actuator to realize automatic remote control.

Multiple safety protections: speed detection, over vibration protection, cover opening protection, overload protection, over temperature protection, peeler action protection, nitrogen protection, electromagnetic interlocking, etc.

Discharge mode: open discharging through chute or integrated discharging with peeler conveyed through spiral.

Variable-frequency control, dynamic braking or energy feedback braking, stepless regulation of speed are designed to realize energy saving, environmental protection and more reliable operation.

Optional configurations: online washing system, nitrogen protection system, steel platform, hydraulic locking device, etc.

Structural Advantages

Dovetail slot design is adopted for door and base fitting flange to ensure reliable sealing.

Full-hydraulic locking door and dual-locking protection are designed to ensure structural reliability and easy operation.

Enclosed and explosion-proof design is employed for the whole structure to meet the GMP standards and the requirements for the application in flammable and explosive places of the pharmaceutical industry.

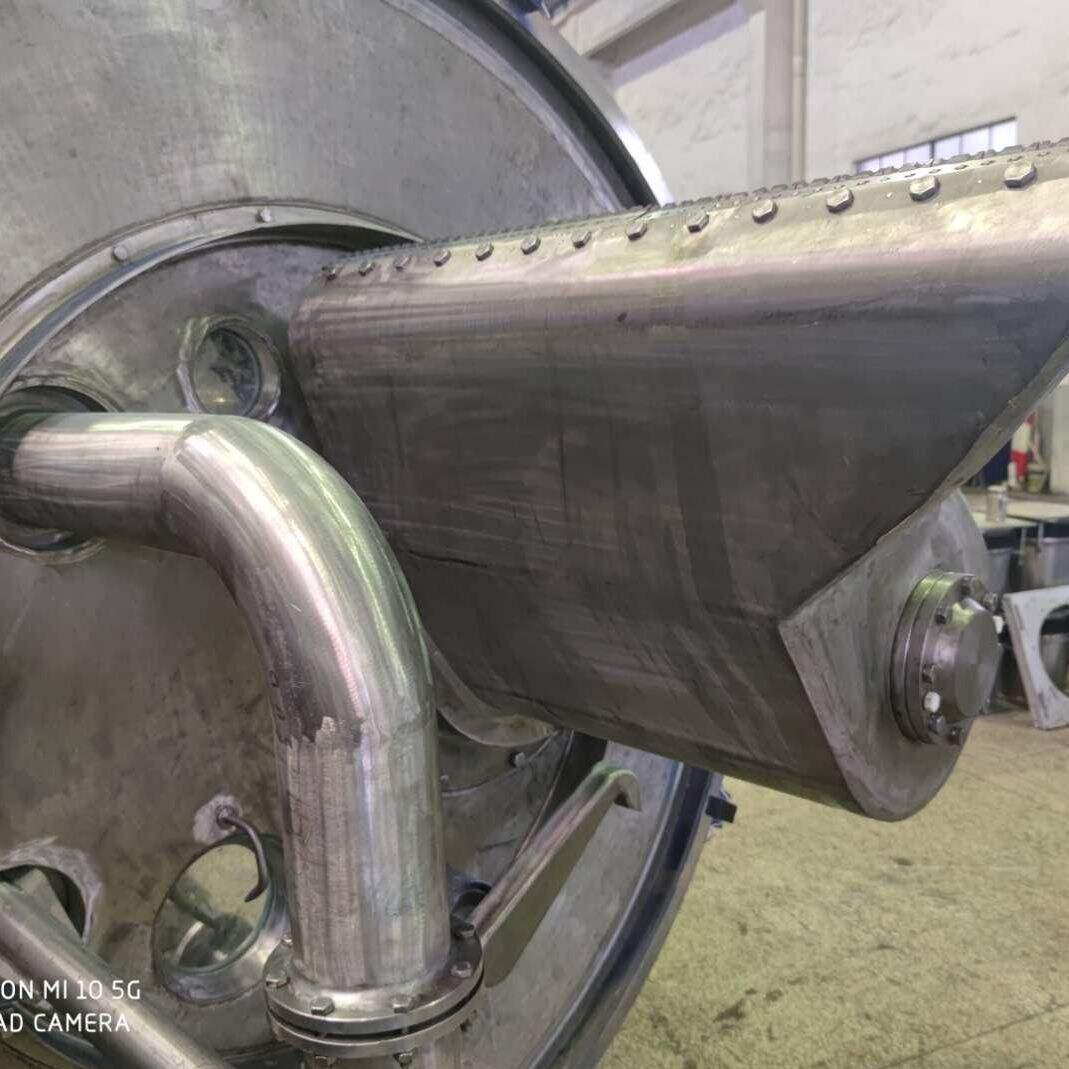

Spiral discharge is adopted to ensure high collection rate of cakes and effectively prevent the blockage of materials.

Peeler support is welded and polished as a whole, with high structural strength and high rigidity to ensure smooth scrapping.

|

Items |

GK600 |

GK800 |

GK1000 |

GK1250 |

GK1600 |

|

Basket Diameter (mm) |

600 |

800 |

1000 |

1250 |

1600 |

|

Basket length (mm) |

325 |

450 |

500 |

600 |

800 |

|

Filter area |

0.61 |

1.13 |

1.57 |

2.45 |

4 |

|

Basket Volume (L) |

45 |

100 |

165 |

355 |

700 |

|

Max. charge (kg) |

60 |

135 |

220 |

460 |

930 |

|

Speed(r/min) |

2400 |

1550 |

1400 |

1200 |

950 |

|

G-Force |

1935 |

1076 |

1098 |

1008 |

808 |

|

Power of Motor (kw) |

22 |

30 |

37 |

55 |

90 |

|

Overall Dimensions (l*w*h) (mm) |

2400*1350*1400 |

2500*1850*1300 |

2800*2000*1550 |

3450*2500*1850 |

4200*2600*2300 |

|

Weight (kg) |

3000 |

3500 |

6000 |

8000 |

15000 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ