HR Pusher Centrifuge

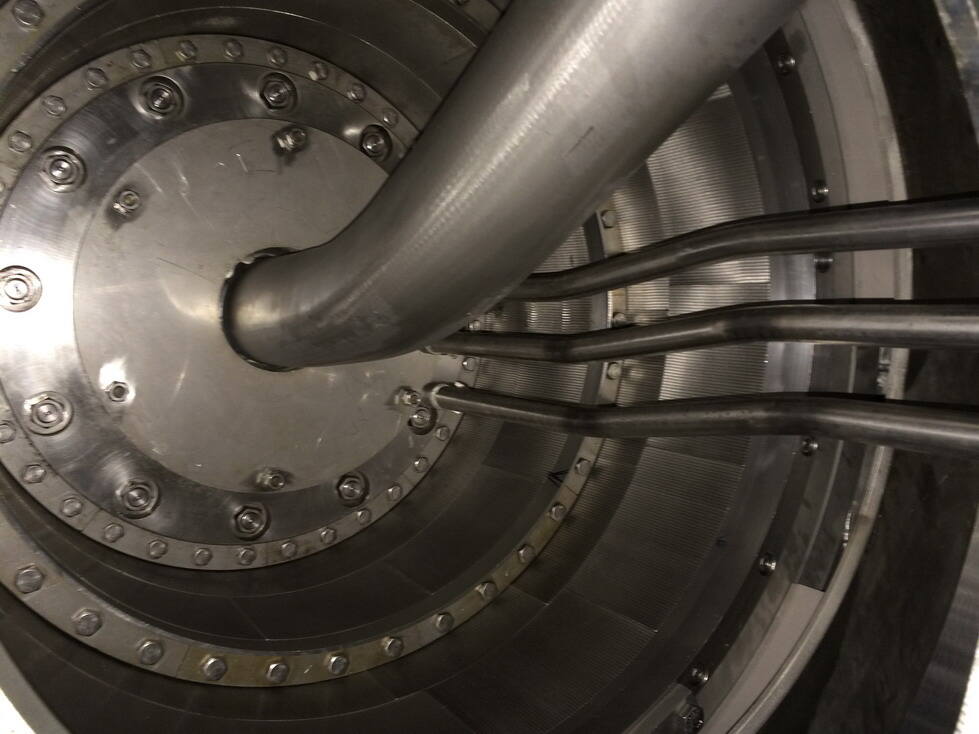

HR pusher centrifuge is a type of filtering centrifuge characterized by continuous feeding and intermittent discharging. Composed of hydraulic system, pushing mechanism, base, enclosure, transmission mechanism, basket, etc., this product is able to realize continuous feeding, separation, washing, discharging and other processes at full speed.

- Overview

- Related Products

Scope of Application

Solid particle size >0.08MM

Concentration of 40%-80% (mass percentage)

Material viscosity <10-1PA.S

Industrial Application

This product is applicable to the filtration of sodium chloride, ammonium chloride, ammonium bicarbonate, urea, polyethylene, polypropyl ethylene, ammonium nitrate, oxalic acid, sodium sulfate, caffeine, etc. in the chemical, fertilizer, alkali production, salt production and other industries.

Working Principle

Driven by the driving motor, the transmission device operates at full speed to bring the materials into the inner basket through the feeding pipe. Under the action of centrifugal force, the materials are evenly distributed onto the screen wall of the inner basket, where the liquid phase flows into the liquid discharge pipe through the screen and pores on the basket wall, while the solid phase is retained on the screen to form a cake layer. The inner basket and outer basket revolve at the same speed. Driven by the piston, the inner basket moves in the axial direction repeatedly and reciprocally to make the pushing tray to push the materials from the inner basket to the outer basket for further separation, where annular cake layers are formed. Continuously pushed by the outer end face of the inner basket, the materials are discharged out of the outer basket and then be conveyed out of the equipment through the material scrapping slot.

Main Features

High separation factor, multi-stage dehydration and washing of materials, with better washing effect and lower moisture content.

Continuous working, large handling capacity, high efficiency, and stable operation.

Low solid content in mother liquid, which can be discharged together with washing liquid or discharged separately.

Low and stable energy consumption.

|

Items |

HR400 |

HR500 |

HR630 |

HR800 |

|

Basket Diameter (mm) |

400 |

500 |

630 |

800 |

|

Filter area length |

320 |

360 |

480 |

600 |

|

Speed (r/min) |

1500-2400 |

1200-2100 |

1000-1800 |

800-1600 |

|

G-Force |

504-1290 |

403-1235 |

353-1143 |

286-1146 |

|

Pushing stroke(mm) |

40 |

50 |

50 |

50 |

|

Pushing times(N/min) |

30-80 |

50-70 |

30-80 |

30-80 |

|

Power of driving motor(kw) |

7.5-15 |

30-55 |

45-75 |

55-90 |

|

Motor power of oil pump(kw) |

5.5 |

22 |

30 |

45 |

|

Weight(kg) |

2400 |

3600 |

3900 |

6100 |

|

Dimension(mm) |

2600*1130*1250 |

3600*1450*1650 |

3130*1430*1360 |

3650*1890*1610 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ