PSD Bag-lifting Centrifuge

Aided mechanical discharge is adopted for the PSD centrifuge. Combining high efficiency of the automatic peeler centrifuge and wide application scope of the top discharge centrifuge, this product is advanced in structural design, small in floor covering area, low in failure rate and high in cost performance.

- Overview

- Related Products

Working Principle

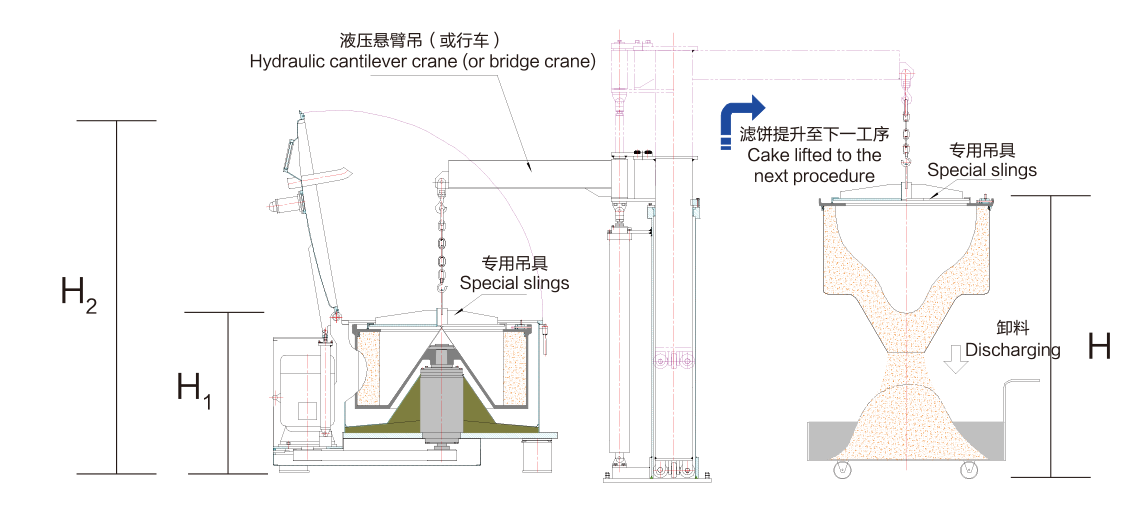

Under the action of centrifugal force, the materials reach the basket wall, where the liquid phase passes through the filtering medium covered on the basket wall and then flows through the pores on the wall to the inner wall of the enclosure, then drops off to the bottom tray and is discharged out via the liquid discharge port. While the solid matters are retained inside the basket and fully washed to complete the solid-liquid separation. After the equipment is shutdown, open the cover, remove the filter bag with special lifting appliances, transfer it to the unloading area for discharging. After that, install the basket lip and filter bag back, lock the basket lip, close the cover and lock it, and at this time, the next circulation can be started.

Scope of Application

This product can be used for the solid-liquid separation of suspensions containing solid particles, as well as for the solid-liquid separation of fibrous materials, such as gypsum, copper sulfate, potassium chloride, borax, dyes, pesticides, salt, monosodium glutamate, food additives, starch, sugar, chemical seasoners, antibiotics, vitamins, copper, zinc, aluminum and other minerals, metal refining, sludge treatment, and sewage treatment has been widely applied in the pharmaceutical, chemical, food, environmental protection, energy and other industries.

Product Features

Low labor intensity and high efficiency: configured with a hydraulic cantilever crane for mechanical discharge.

Grains less prone to breakage: special-purpose slings used to lift and discharge the materials as a whole.

Stable operation: low gravity center of the equipment designed and liquid damping device adopted to attenuate vibration.

Easy replacement of filter cloth: basket lip designed with special structure that can be disassembled fast.

Cover opening mode: hydraulic drive and mechanical drive.

|

Items |

Models |

||||||

|

PSD800 |

PSD1000 |

PSD1200 |

PSD1250 |

PSD1500 |

PSD1600 |

PSD1800 |

|

|

Basket Diameter (mm) |

800 |

1000 |

1200 |

1250 |

1500 |

1600 |

1800 |

|

Effective basket height(mm) |

450 |

520 |

550 |

630 |

680 |

800 |

750 |

|

Basket Volume (L) |

120 |

200 |

270 |

400 |

550 |

800 |

910 |

|

Max. Load (kg) |

150 |

250 |

340 |

500 |

700 |

1000 |

1100 |

|

Max. speed (r/min) |

1500 |

1200/1400 |

1100 |

1000/1200 |

850 |

850 |

780 |

|

G-Force |

1007 |

805/1096 |

812 |

700/1007 |

606 |

647 |

612 |

|

Motor (kW) |

7.5 |

11/15 |

15 |

18.5/22 |

30 |

37 |

37 |

|

Dimension (L*W*H) (mm) |

1730*1200*1300 |

2000*1400*1500 |

2300*1600*1500 |

2550*1800*1780 |

2600*2300*1800 |

3200*2400*2150 |

3300*2600*2100 |

|

Weight (kg) |

1500 |

2500 |

3800 |

4000 |

6000 |

9000 |

10000 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ