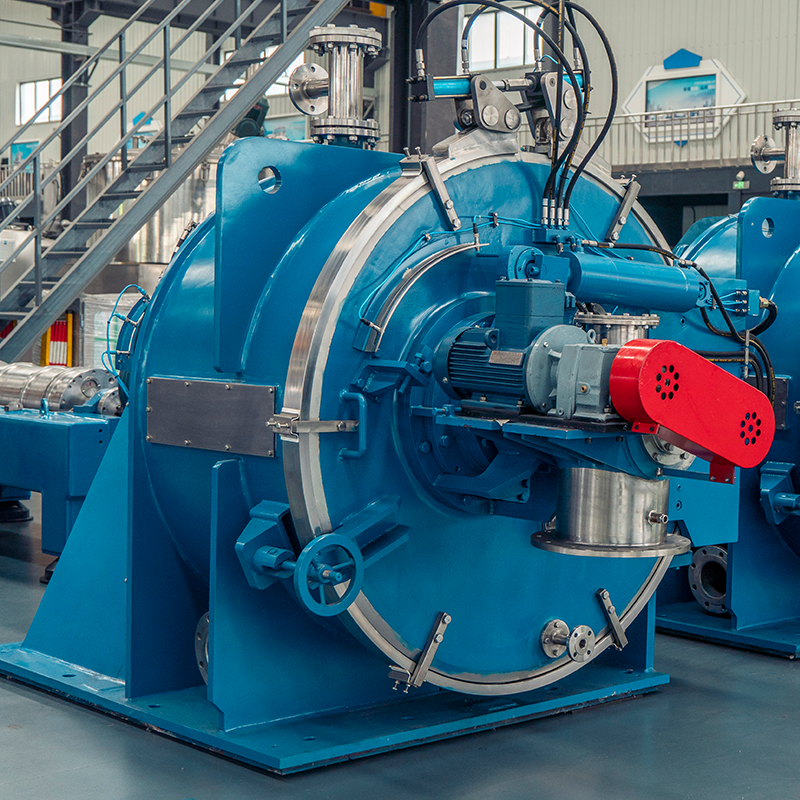

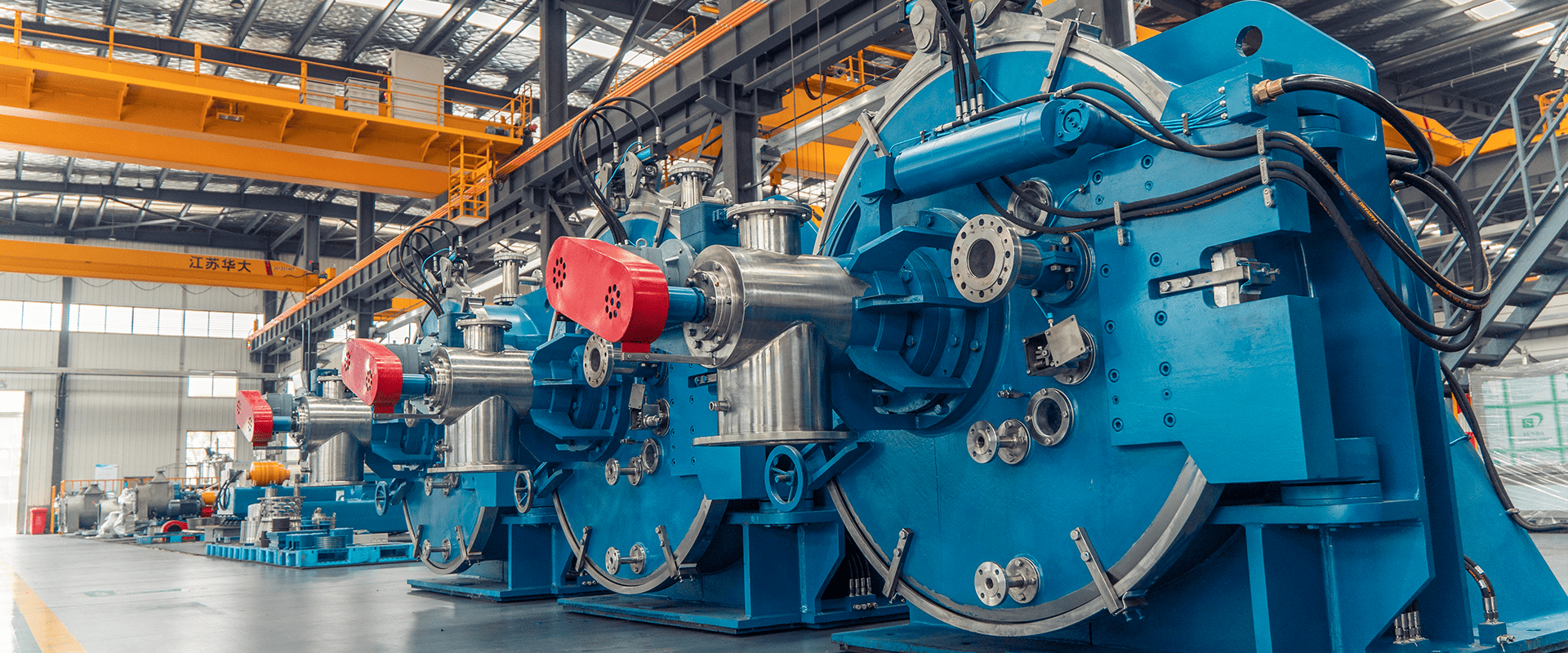

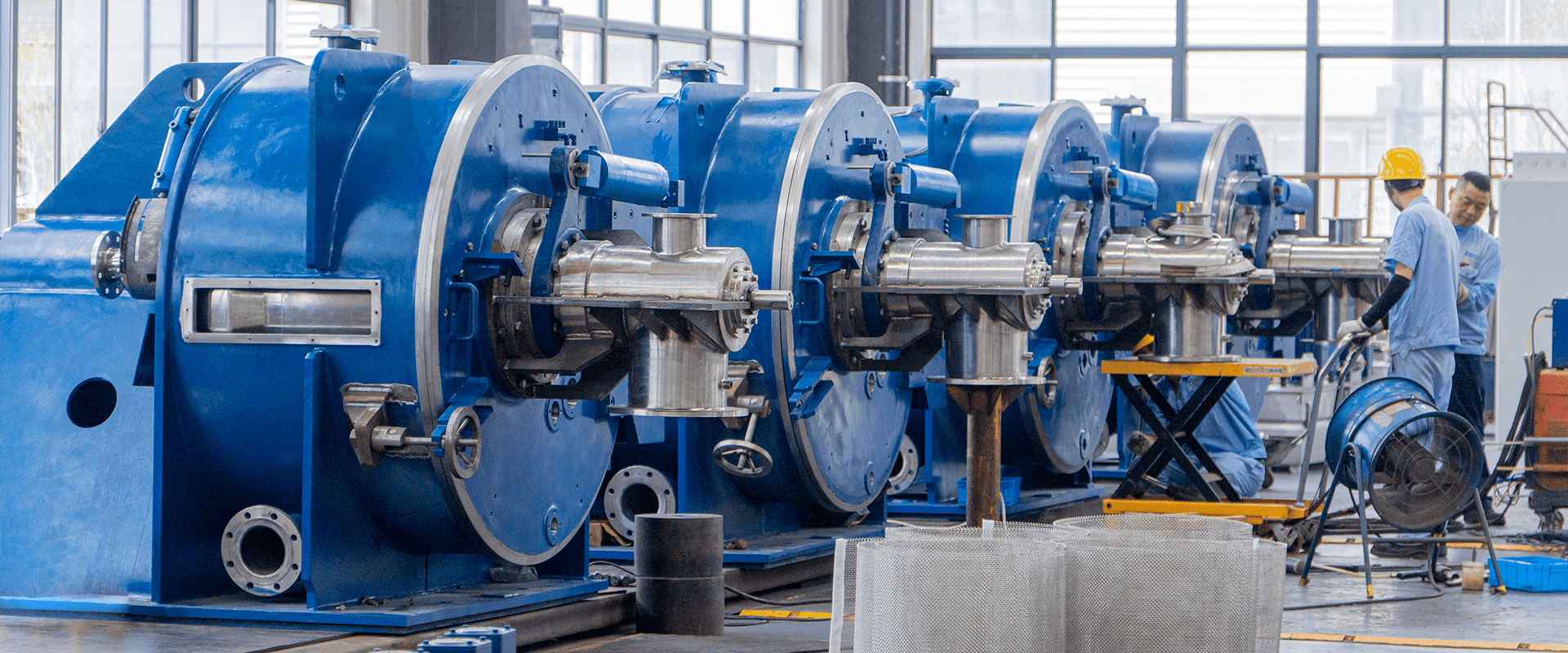

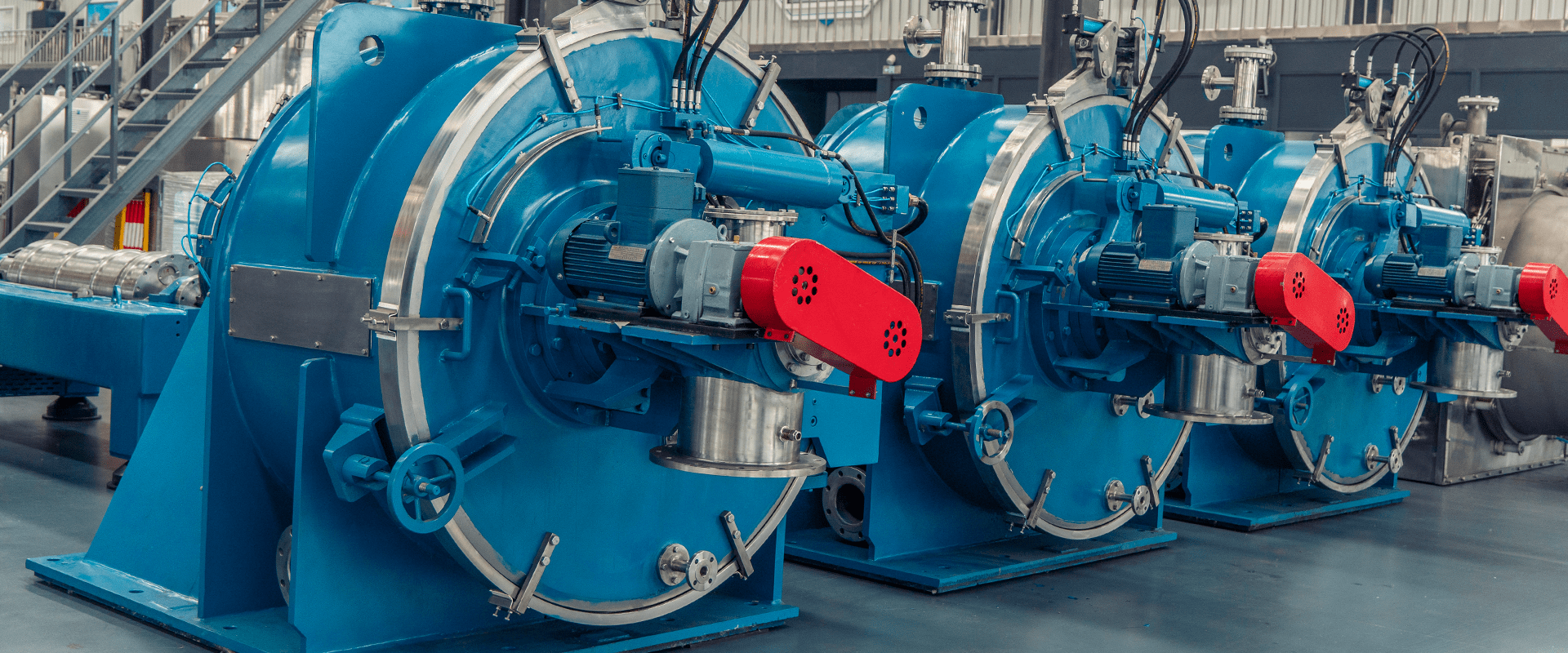

GKH Siphon Peeler Centrifuge

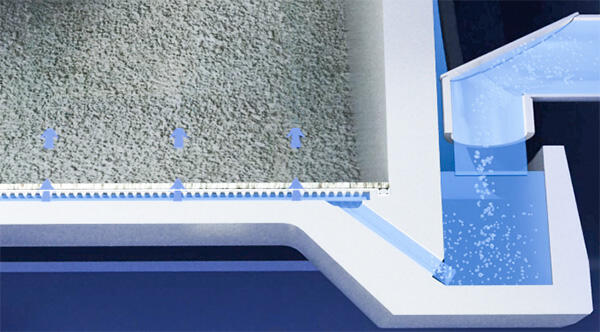

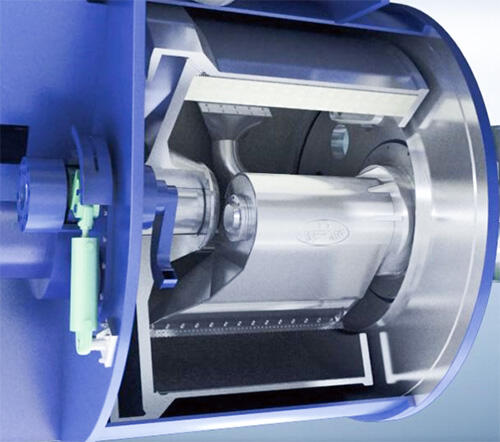

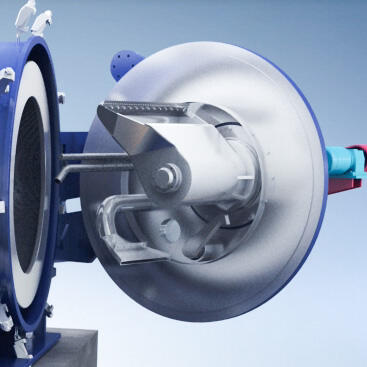

GKH siphon centrifuge is a new type of product that is developed on the basis of the ordinary peeler centrifuge. Based on the siphon principle, this product discharges the filtrate out via a siphoning device or skimming device. The filtering impetus can be changed by adjusting the liquid level at the suction inlet of the siphon pipe (skimming pipe) to further regulate the filtering rate, handling capacity, cake moisture and washing effect. A back-flushing device is configured to realize regeneration of the filter cloth and improve the separation effect. With back-flush, scouring, siphoning and other functions by configuring special devices, the filter cloth can be regenerated completely.

- Overview

- Related Products

The siphon-type peeler centrifuge is applicable to the occasions involving large-scale production and requiring low cake moisture and sufficient washing, and therefore is commonly used for the separation of starch, sodium bicarbonate, potassium chloride, calcium phosphate and other materials. Currently, it has been widely applied in such industries as pharmaceutical production, food production, bioengineering and chemical engineering.

Advantages of Siphon Peeler Centrifuge

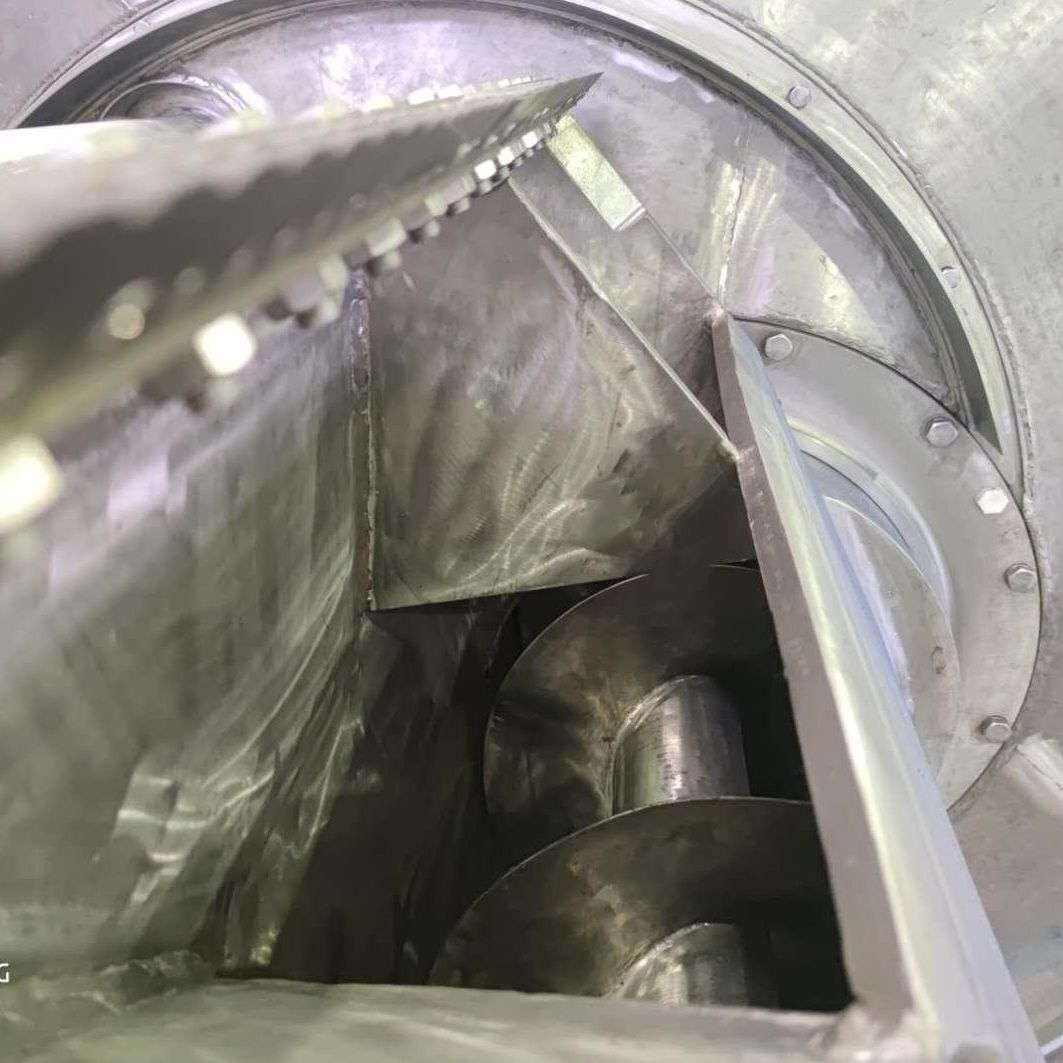

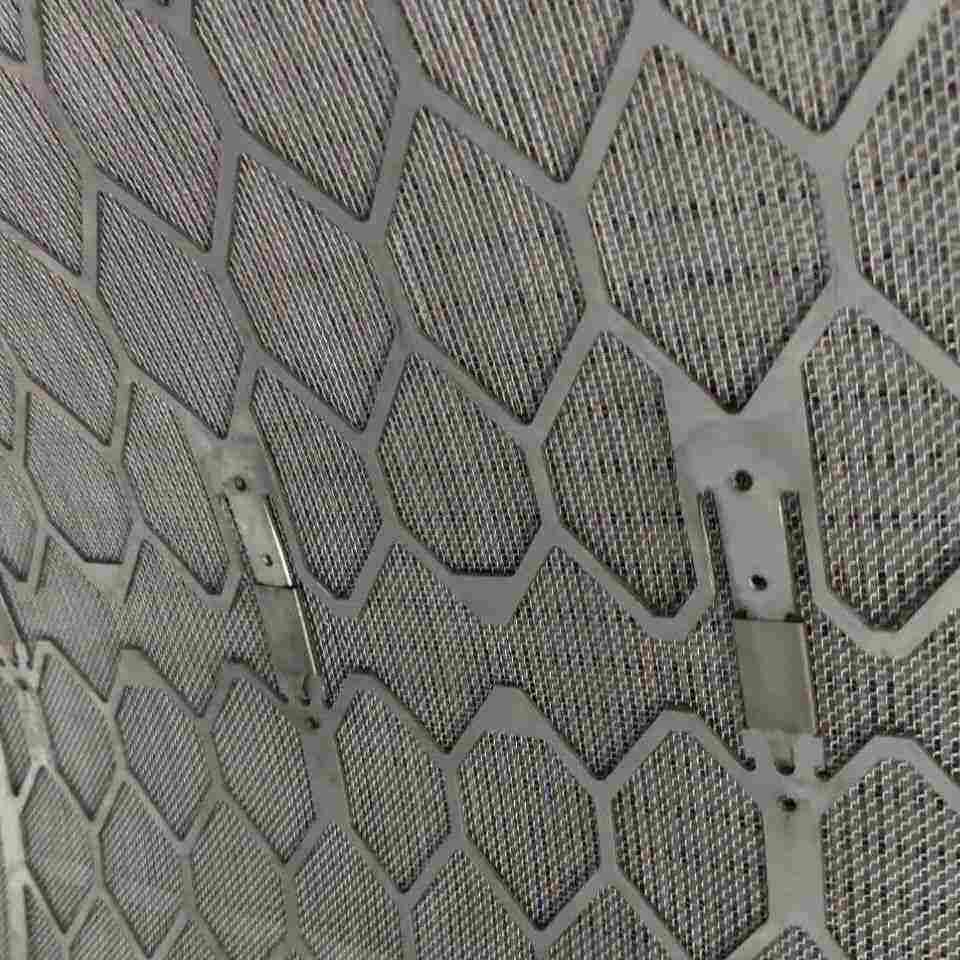

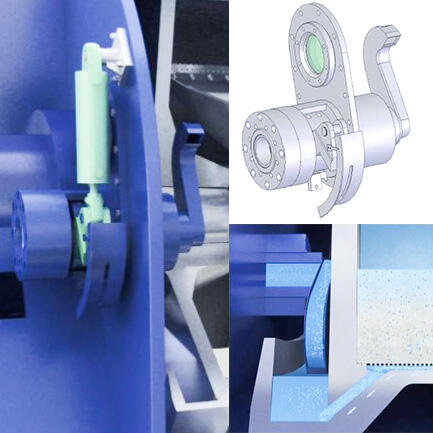

Back-flushing Device

Residual cake and filtering medium soaked and flushed reversely to realize regeneration of filter cloth.

Skimming Device

Applicable to the separation of materials containing protein, colloidal substances, etc.

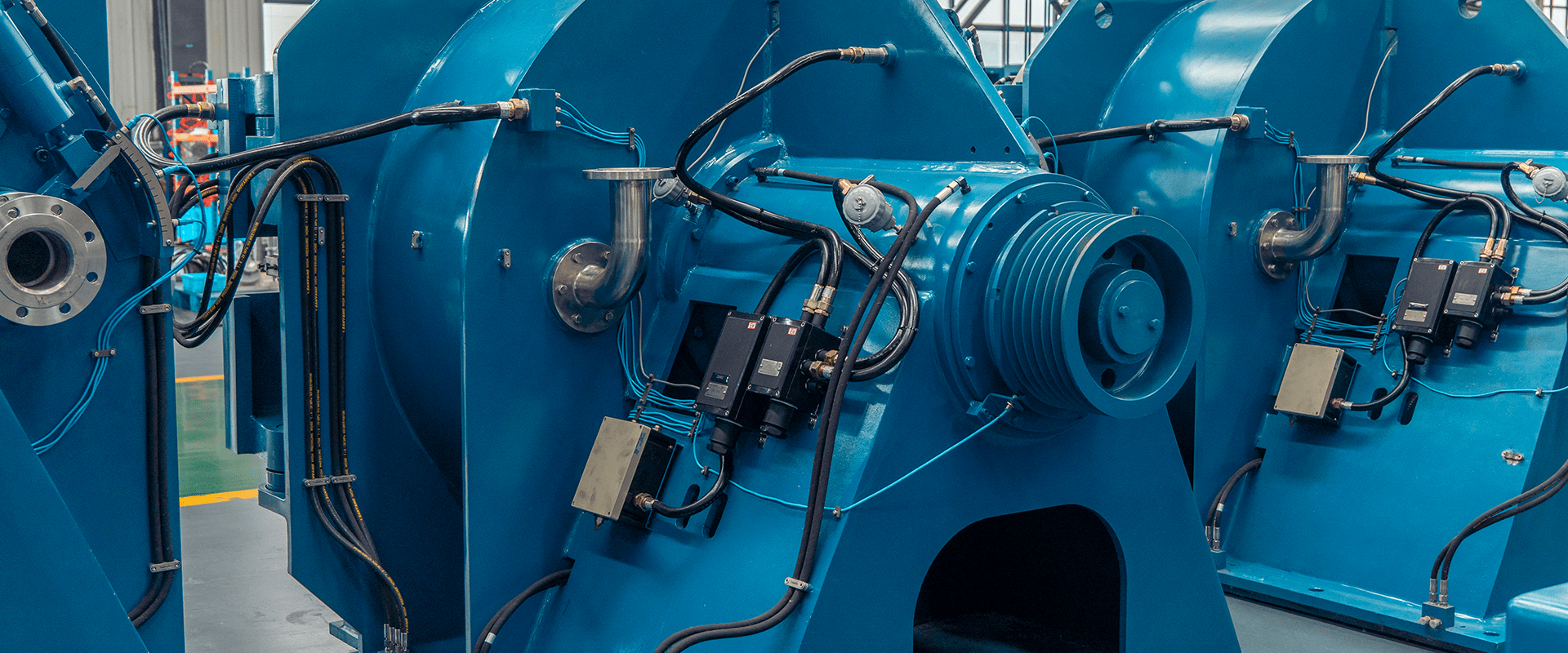

Three-position control designed to complete separation, dehydration, washing and other processes, and ensure accurate angles, with good reproducibility.

|

Items |

GKH800 |

GKH1000 |

GKH1250 |

GKH1600 |

|

Basket Diameter (mm) |

800 |

1000 |

1250 |

1600 |

|

Basket Length (mm) |

450 |

500 |

625 |

1000 |

|

Filter area |

1.13 |

1.57 |

2.36 |

5 |

|

Basket Volume (L) |

100 |

165 |

355 |

830 |

|

Max. Load (kg) |

135 |

225 |

450 |

1000 |

|

Speed (r/min) |

1550 |

1400 |

1200 |

950 |

|

G-Force |

1078 |

1098 |

1008 |

808 |

|

Motor (kW) |

45 |

55 |

90 |

132 |

|

Dimension (L*W*H) (mm) |

2550*1850*1350 |

2400*2150*1700 |

3450*2200*2800 |

5050*2750*2300 |

|

Weight (kg) |

4500 |

6500 |

9000 |

17000 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ