- Overview

- Related Products

Advantages of LW Centrifuges

Increase the handling capacity

Extend the decanting duration and reduce the solid content in the clarified liquid to achieve 99% recovery of materials (maximum)

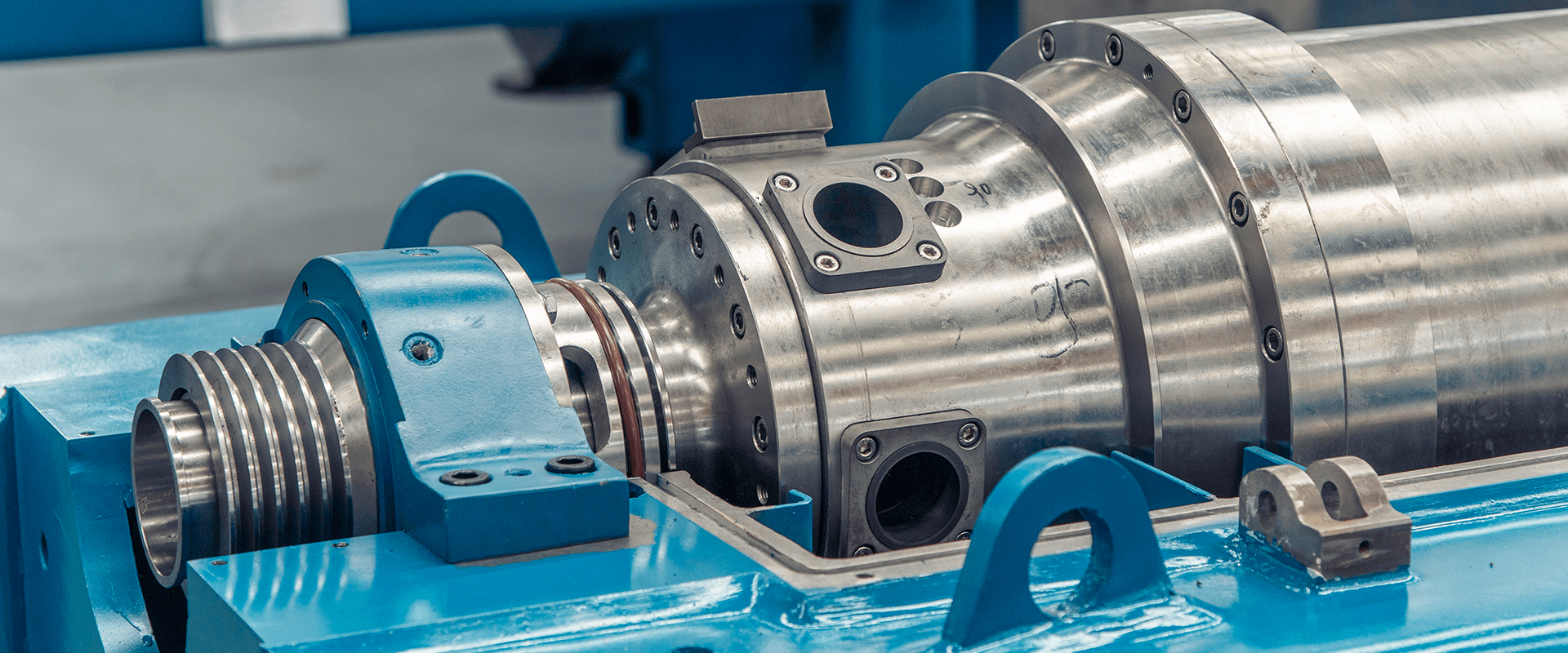

Centrifugal casting is adopted for manufacturing the Bowl and spiral shaft to improve the structural strength significantly

Wear resistance, prolonged service life and low maintenance cost

Axial wear-resistant steel is adopted for the Bowl, and replaceable wear-resistant sleeve (hard alloy or porcelain sleeve) is adopted for the feeding port and deslagging port

Hot-sprayed hard alloy sheets, inlaid hard alloy sheets or high wear-resistant porcelain sheets are configured for screw blades

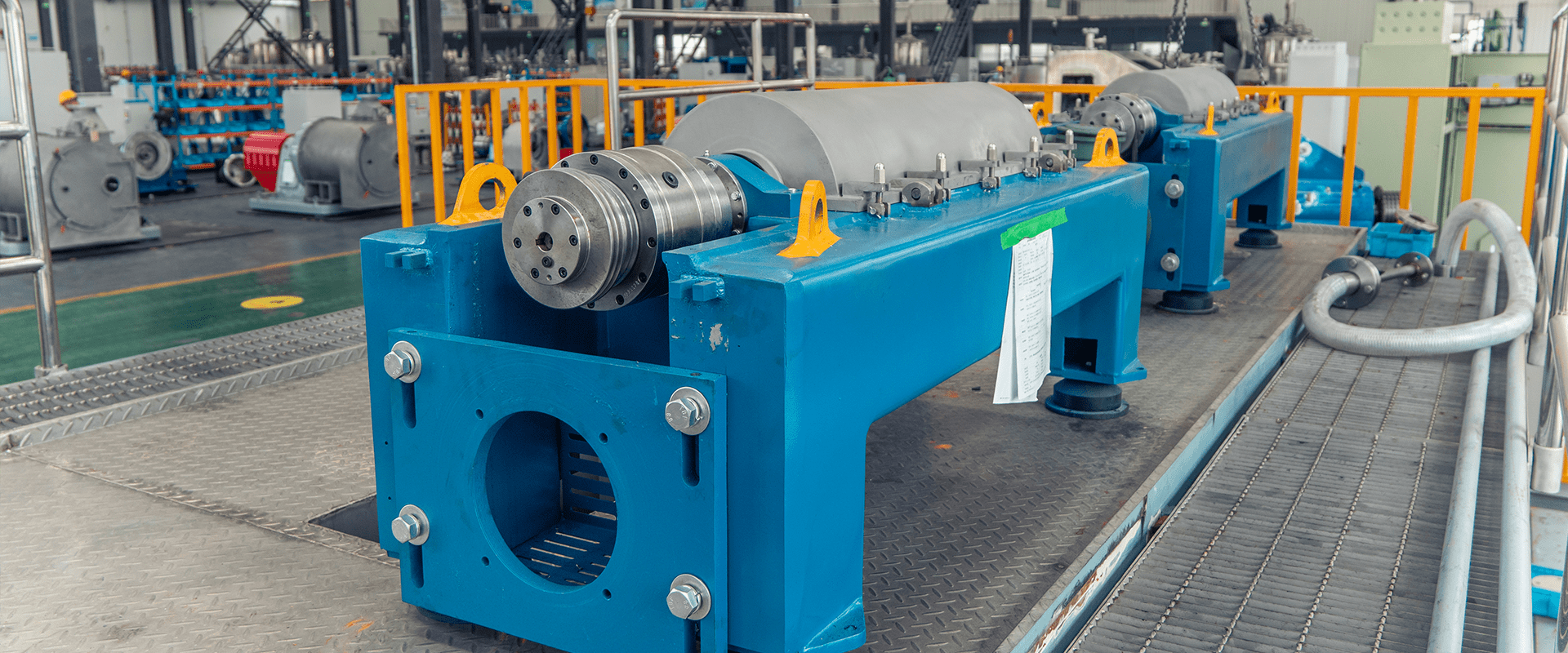

LW Decanter Centrifuge (Standard Type)

Labyrinth seal is adopted for both ends of the Bowl of the standard type of the LW series, which is simple yet efficient. After separation, the solid phases are pushed to the solid discharge outlet through a spiral and then discharged out of the Bowl under the action of the centrifugal force generated from high-speed revolution, and the clarified liquid is discharged out of the overflow port at the big end of the Bowl. Featuring simple operation, stable operation, high efficiency and high automation, and continuous working of 24 hours, this type is widely applied.

LWX Decanter Centrifuge (Centripetal Pump Type)

Materials enter the equipment through the feeding pipe. Under the action of centrifugal force, the solid phases will deposit to form a sediment layer on the Bowl wall, and the liquid phases will form a liquid ring, successively forming a solid layer and liquid layer inward from the Bowl wall. The spiral works continuously to push the solid matters on the Bowl wall to the conical end of the Bowl and then discharge them out of the equipment through the slag discharging port. And the liquid phases are discharged out through the centripetal pump at the big end of the Bowl.

As the liquid after separation is discharged through the centripetal pump with certain pressure, the suspension can be conveyed horizontally for a certain distance, thus to replace a relay pump and save energy. Meanwhile, the possibility of a secondary contact between the tiny droplets and solid matters after the discharge of suspension can be completely avoided as they are at different cavities when discharged, so high-degree cleanliness can be ensured, making the product applicable to pharmaceutical and food production, and other fields.

LWFX Decanter Centrifuge (Explosion-proof Type)

This type of centrifuge is mainly used in the chemical, petrochemical and pharmaceutical industries involving flammable and explosive occasions. In the process of solid-liquid separation, gases are not allowed to leak into the extraneous air, or extraneous air is not allowed to enter the equipment, or it may lead to explosion. The product is configured with an airtight seal with automatic compensation function, which allows a dynamic enclosed space with micro-positive pressure to be formed inside the centrifuge during the process of operation, so as to realize good sealing and explosion-proof effect.

|

Models |

Bowl Diameter (mm) |

L/D Ratio |

Bowl Speed (r/min) |

G-force |

Main Motor Power (kW) |

Weight (kg) |

Dimension (L*W*H) (mm) |

|

LW220*880 |

220 |

4 |

4800 |

2840 |

11 |

1000 |

2660*740*780 |

|

LW300*1390 |

300 |

4.3 |

4400 |

3250 |

15 |

1500 |

3250*960*1000 |

|

LW355*1460 |

350 |

4.17 |

4000 |

3130 |

22-30 |

2200 |

3550*1010*1030 |

|

LW450*1800 |

450 |

4 |

3200/3600 |

2580/3265 |

30-37 |

3500 |

4150*1090*1250 |

|

LW450*2025 |

450 |

4.5 |

3200/3600 |

2580/3265 |

30-37 |

4000 |

4350*1090*1250 |

|

LW530*2120 |

530 |

4 |

2800 |

2330 |

45-55 |

5300 |

4850*1230*1450 |

|

LW530*2650 |

530 |

5 |

2500 |

1850 |

55 |

6000 |

5400*1230*1450 |

|

LW650*2800 |

650 |

4.3 |

2500 |

2270 |

90 |

9600 |

5400*1750*1600 |

|

LW720*2880 |

720 |

4 |

2000 |

1610 |

110 |

11000 |

5300*2050*1750 |

|

LW850*3200 |

850 |

3.76 |

2000 |

1900 |

160 |

16000 |

6750*2280*1900 |

|

LW1000*3000 |

1000 |

3 |

1500 |

1260 |

132 |

16000 |

5200*2500*2000 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ