- Overview

- Related Products

Working Principle

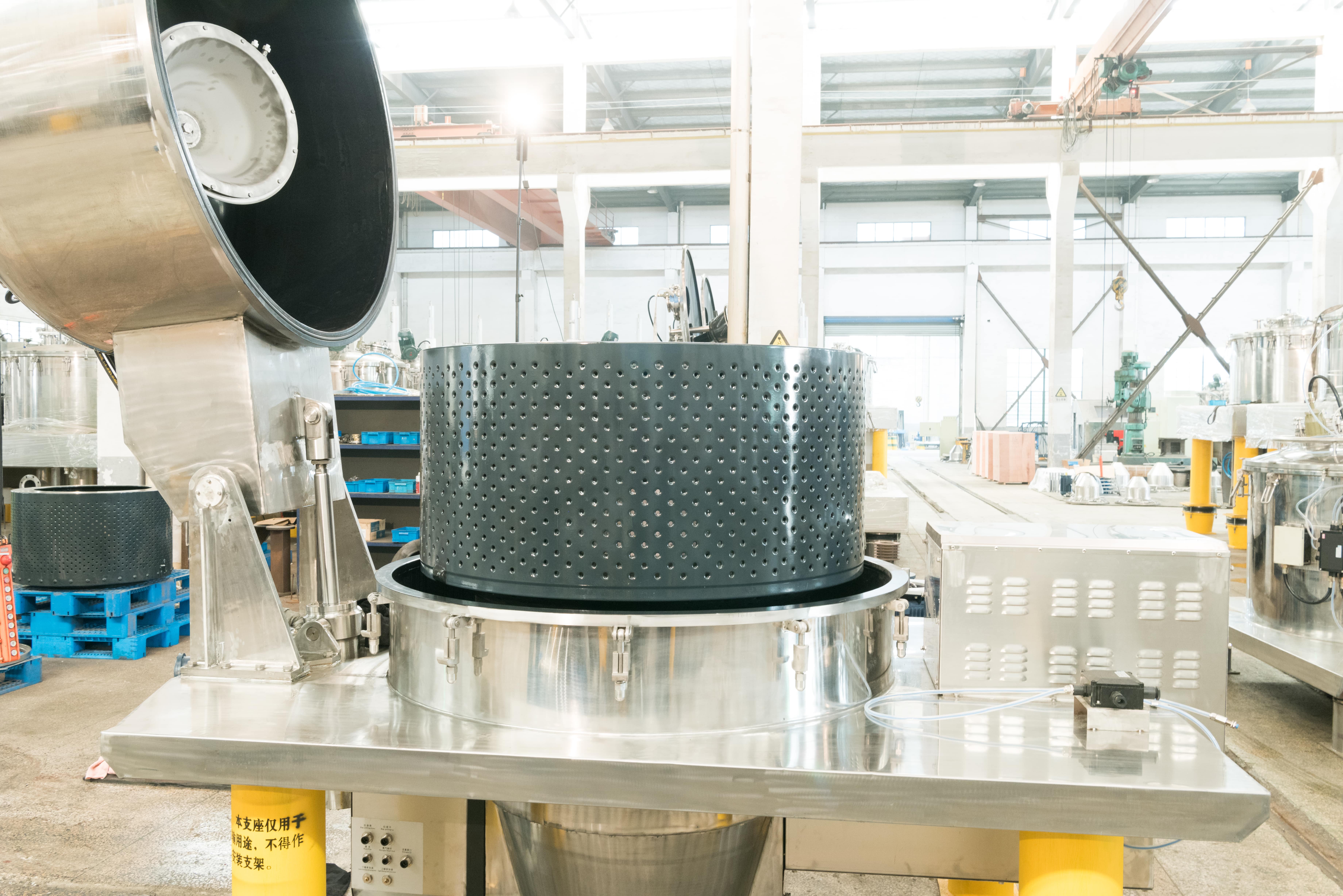

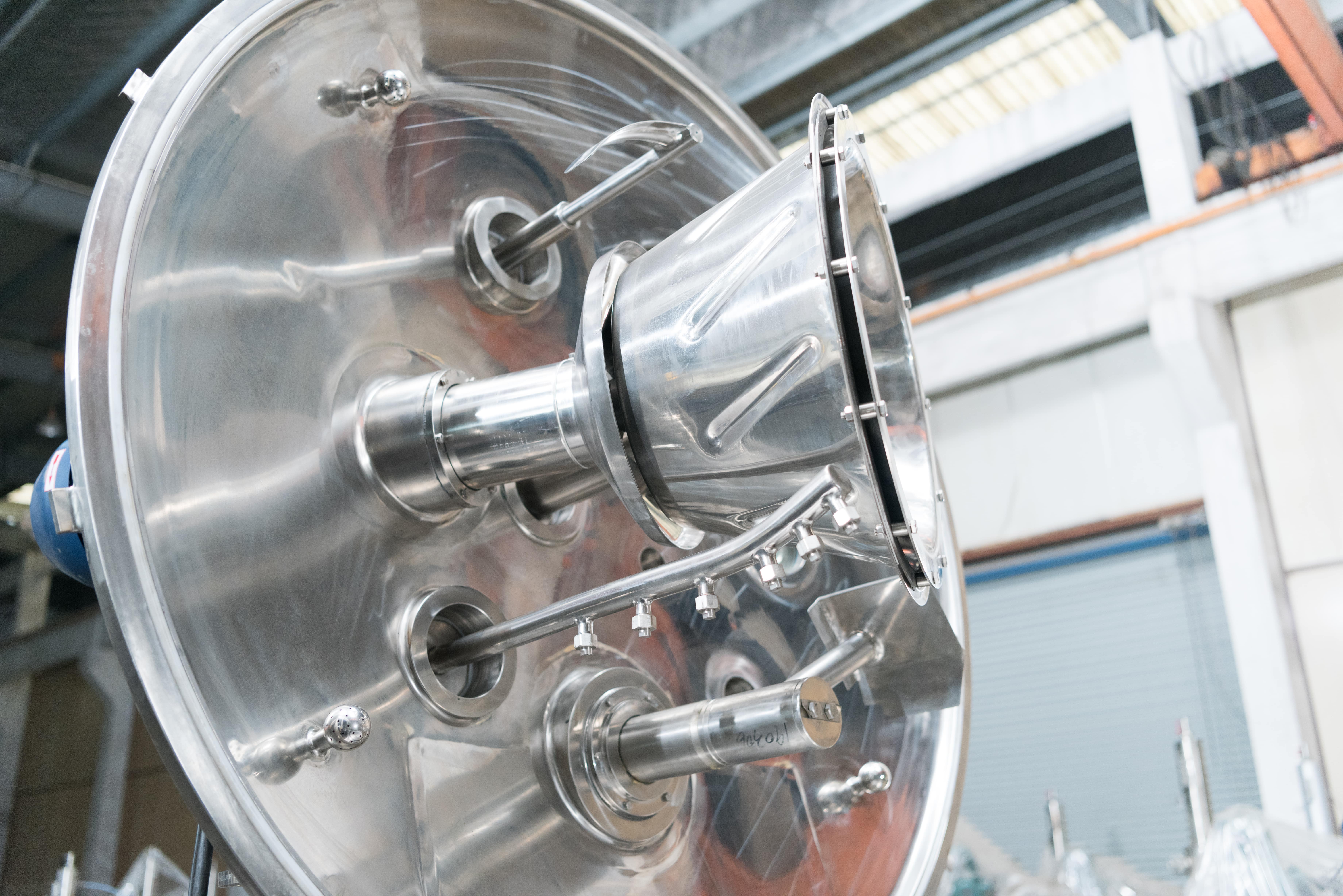

Materials to be separated are added into the high-speed rotating centrifuge basket through the feeding pipe. Under the action of the centrifugal field, the material will be filtered through the filter cloth, the liquid phase will be discharged through the liquid outlet, and the solid phase will be retained in the basket. When the basket is filled with materials and the feeding and dehydration stop, wash the cake and filter out the washing liquid. The centrifuge continues to spinning to dry the filter cake. After the cake meets the separation requirements, the centrifuge slows down and the scraper removes the cake from the bottom and out of the machine. Then, the centrifuge slows down again and the pneumatic bag puller moves up and down to shake off the residual cake, so as to completely remove the cake.

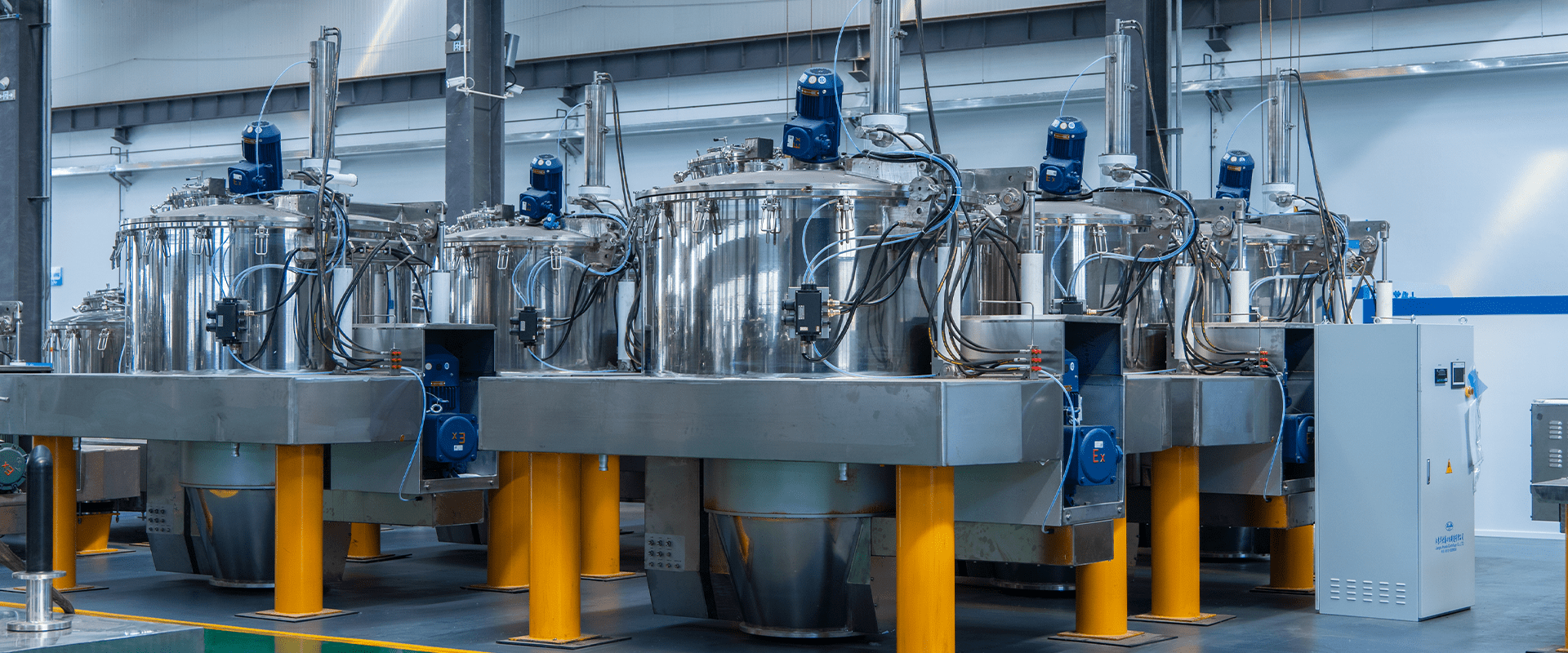

PQLD Pharma Centrifuges

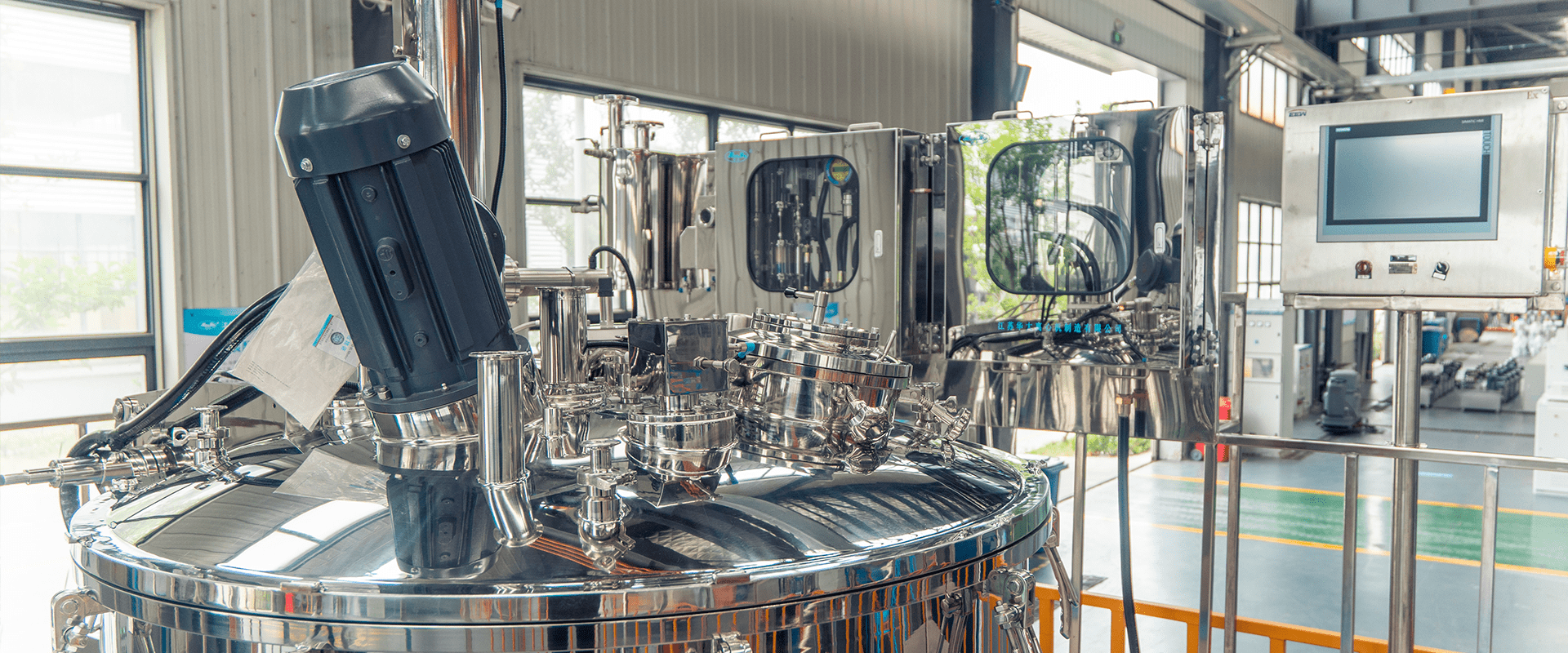

The Cover can be opened fully, and the transition of the whole structure is smooth and flat, which can give a thorough cleaning, effectively putting an end to the dead corners and can remove online residuals to avoid cross-contamination of materials. It is suitable for material separation requiring high purity and hygiene.

Main Features

Cake removal rate higher than 99%

The filter bag is designed with a renewable structure and it can well remove the residual cake, avoiding cross contamination of materials. Moreover, it can improve the filtering efficiency and prolong the service life of the filter bag.

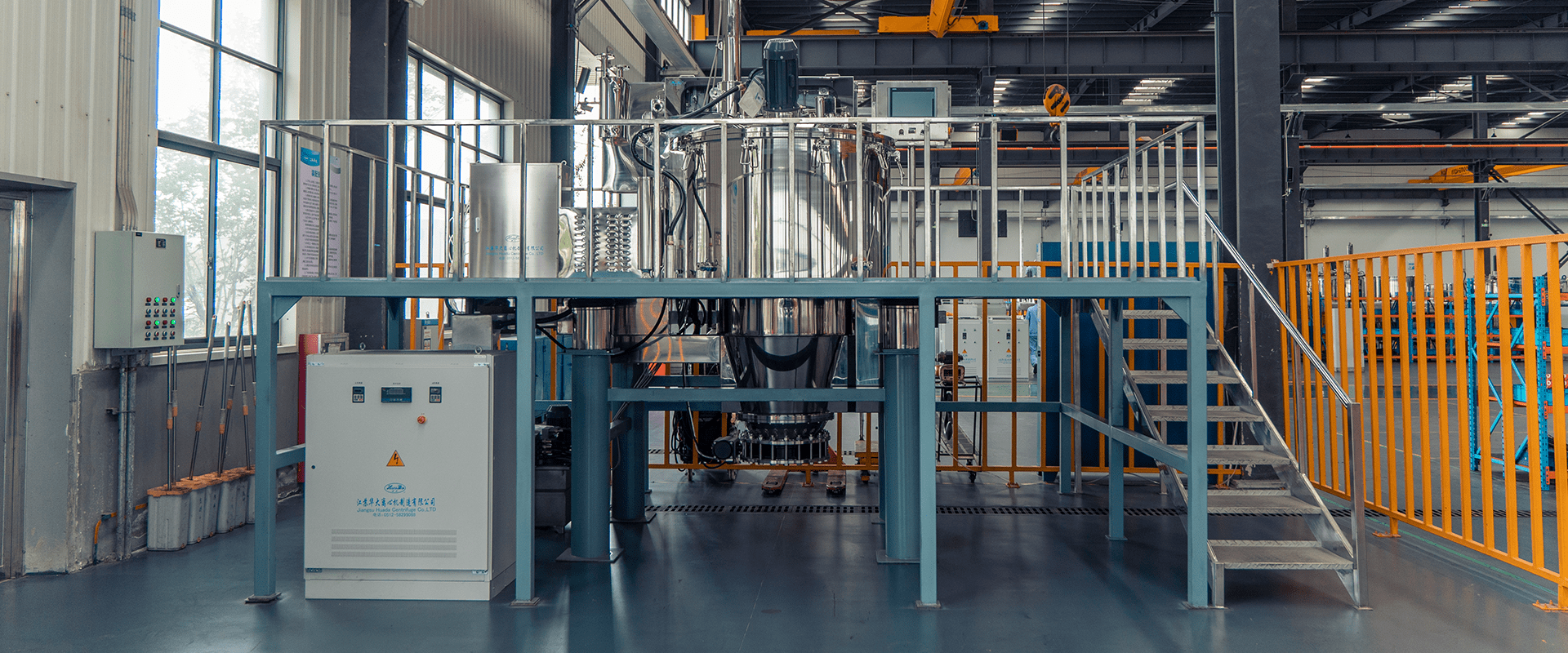

Compliance with GMP specifications and anti-explosion requirements

The structure of large cover or whole housing reversible+ CIP online cleaning system can achieve thorough cleaning in centrifuges.

Small vibration, low noise and stable operation: The liquid damping shock absorber technology is adopted, and it is installed without base, which effectively reduces the vibration of the centrifuge and facilitates the installation and maintenance of the machine.

The basket is comprehensively machined and undergoes 100% weld flaw detection, with high machining precision and large filtering area, conducive to ultrafine particle filtration.

|

Items |

Models |

||||

|

|

PLD800 |

PLD1000 |

PLD1250 |

PLD1400 |

PLD1600 |

|

Basket Diameter (mm) |

800 |

1000 |

1250 |

1400 |

1600 |

|

Basket volume (L) |

100 |

180 |

400 |

600 |

800 |

|

Max. load (kg) |

130 |

230 |

500 |

700 |

1000 |

|

Max. speed (r/min) |

1200/1500 |

1100/1200 |

1000/1200 |

950 |

850 |

|

G-force |

645/1007 |

677/805 |

700/1008 |

700 |

647 |

|

Motor (kW) |

7.5/11 |

15 |

22/30 |

30 |

37 |

|

Dimension (L*W*H) (mm) |

2050*1250*2000 |

2200*1530*2200 |

2550*1800*2550 |

3000*2100*2720 |

3200*2400*3000 |

|

Weight (kg) |

2000 |

3500 |

5000/6000 |

9000 |

12000 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

IS

IS

LO

LO

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ