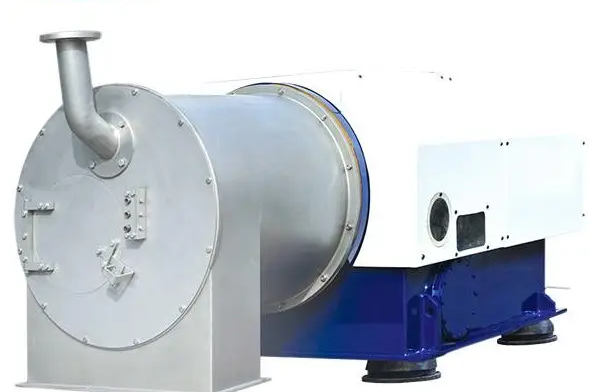

With an intention for better rotary solid liquid separation, a wide range of industries is this decanter centrifuge’s application, which provides an ideal one. This equipment is continuously in operation and has the capability of dealing with large quantities, thus being well-suited to industries such as waste water treatment, chemical production and food industries.

Centrifugation is the process of separating a mixture using centrifugal force. In this case, the rotating decanter achieves the separation of solids from liquids through the use of centrifugal force. This allows the separation of finer particles than would be possible in conventional separation methods and indicates high degrees of clarity. Its effective structure allows use and operation in harsh conditions.

The machine is fully equipped with control settings and mechanisms such as control systems, speed optimization as well as structural designs of the bowl where various processes could be performed to ensure optimum operational parameters are fitted. Because of its lean low maintenance and energy consumption, it is the best option for improving operational capacity while lowering operating costs. Solids, sludges, slurries and other mixtures are some of the feed material for the decanting machine and high performance and consistency is clearly evident in material separation.

Decanter centrifuges, unlike many industrial machines, are multifunctional. Every industry segment has its specialization in terms of decanting. Solids have to be removed efficiently from the liquids in a number of industries like mining, oil and gas, food industries, and pharmaceuticals. The separating mechanism relies on generated centrifugal force for separating the components based on the differences in densities which completes the process of separation in a short time as compared to other methods. The concept behind building a decanter centrifuge is based on the continuous feed which suits high volume industries. Additional, the decanter centrifuge is also used to process slurries that contain a lot of solids, allowing engineers to efficiently complete even the most difficult projects. Low operational costs accompanied by high volume output makes the decanter centrifuges productive appliances in enhancing industrial processes.

As stated earlier one of the benefits of a decanter centrifuge is that it decreases waste in the industrial processes A decanter centrifuge reduces the percentage of waste generations by improving separation of solids and liquids which makes it possible for industries to recycle essential components and reintroduce them into the manufacturing process This further minimises the waste disposal expenditures and therefore promotes sustainability of the operation The decanter centrifuge, due to its capability of processing large dumps of materials will run therefore continuous processes which have constant high wastage volumes such as when handling wastewater and chemical industries The spinning of the particles at high speeds results in almost complete separation of all particle sizes such that no valuable material is left behind The wastage minimisation and resource reclamation efficiency exhibited by the decanter centrifuge makes it a strategic tool in the performance of pollution free industries

The decanter centrifuges are the machines which are efficiently used for the solid-liquid separation in the various industrial processes Thanks to its special configuration it can be applied for a wide range of materials such as sludge, slurry, and other mixtures making it useful in industries that require reliability in separation of materials The separation method is facilitated by speed which causes centrifugal force that ensures the heavier solids are deposited and the liquids pushed away The decanter centrifuge is in widespread use in environments such as wastewater treatment plants, food industries, chemical plants, and such like industries where effective separation of liquids from solids is required Pretty much every aspect of this separation technique increases the productivity and maximizes the reduction of wastes and factors of the separated constituents’ quality This sturdy construction gets rid of worries of repair and replacement failures in hostile working environments hence it’s worth in every industry

The decanter centrifuge is crucial making industrial processes more productive By offering a steady and mechanized process of solid liquor separation there is no further use of the operator nor of the traditional filtering practices This leads to a quicker way of performing these activities hence increasing both the output and reducing the time taken Further, the structure of decanter centrifuges makes it possible to process a wide range of materials which makes cross boundary applications and industries easy The design of how one works these machines include factors like speed and the feed rate To them, they are also potential performance enhancers in regard to the design of the centrate flow path Therefore, with this capability and the strong construction of decanter centrifuges, this ensures that they are still main contributors in enhancing industrial activities globally

Jiangsu Huada Centrifuge Co., Ltd., a subsidiary of SCIMEE (stock code: 300425), was established in 1993 in China. We are a leading Chinese centrifuge manufacturer. Over the years, HUADA has always focused on the research and development, production and sales of filtration and separation machinery, and has insisted on building an open and win-win cooperation system to lead the industry with scientific and reasonable technological innovation, win the market with specialized and standardized customer service, guarantee quality with excellent management and provide solutions to the solid-liquid separation problems for each customer with concentrated attention.

25

Sep

25

Sep

25

Sep

A decanter centrifuge is used to separate solids from liquids in a slurry. It works by rotating at high speeds, creating centrifugal force that separates particles based on density. This makes it an efficient tool for industries like wastewater treatment, oil refining, and food processing, where solid-liquid separation is essential.

A decanter centrifuge enhances efficiency by continuously processing large volumes of slurry, reducing the need for manual filtration. Its automated operation allows for consistent separation of solids and liquids, minimizing downtime and increasing productivity, especially in industries requiring high throughput.

When choosing a decanter centrifuge, consider the capacity, speed, and material of the machine. The type of slurry, particle size, and required separation level will dictate the appropriate centrifuge model. Additionally, factors like ease of maintenance and energy consumption should be evaluated to ensure long-term cost-effectiveness.

Copyright © 2024 Jiangsu Huada Centrifuge Co., Ltd. All Rights Reserved Privacy policy