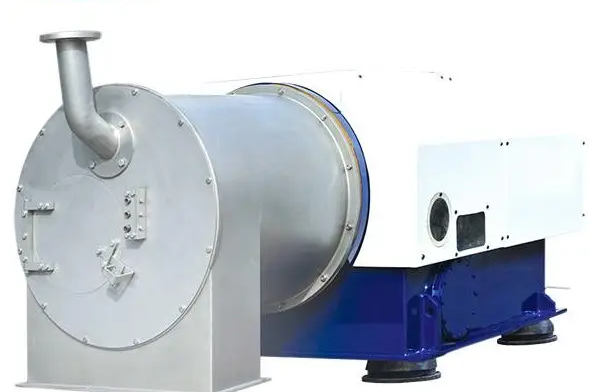

Kalamabangi, L. (2017) states that the auto scraper bottom discharge centrifuge is specially designed for high separation in most industrial applications, where safety and performance are given the utmost attention. The unique feature of this advanced centrifuge is the presence of auto scraper which guarantees that solid discharge takes place continuously and effectively without compromising the speed and stability of the operation.

This sanitization machine is constructed as a centrifuge for liquids containing solids rather than other types of centrifuges without solids. The reasoning of such efforts expansion is its bottom discharge for convenient active and autonomous removal of any accrued solids resulting in limited inactivity time and improved performance.

High-quality materials have been used in the construction of such an equipment for corrosion resistance, ruggedness against wear and tear etc auto scraper centrifuge features. A sufficient range of such controls is usually placed on a control panel to which operators are able to use the system intelligently and make specific adjustments as required, enhancing the efficiency in the separation of the different substances.

Ultimately, the auto scraper bottom discharge centrifuge is very compact and operates with minimal energy consumption which makes it advantageous to the industries which are in need of enhancing their separation processes at a cost that will not compromise labor and the environment. This perfectly reliable and cutting edge apparatus is a perfect illustration of the advantages offered by advanced separation technique.

With business competition at its peak, the level of production efficiency becomes an important factor and the auto scraper bottom discharge centrifuge provides that Well, partial automation of the discharge process eliminates the imperfections caused by hand work and these lead to decreased cycle times enhancing the cost efficiency This is also increasing revenues and decreasing costs. As industries try to satisfy the growing demand, the centrifuge becomes one of the great machines that not only improves productivity but also guarantees quality With the ability to process a large amount of material without failure it forms one of the essential elements of modern processing equipment

The auto scraper bottom discharge centrifuge is a centrifugal separator which sits atop the other centrifugal separator considerably boosting material processing that is intended for various applications. This centrifugal separator does away with the need for human discharge making the separation of solids from liquids more effective. The high degree of centrifugal action used can be regarded as a separator leveler which is why most manufactures tend to include such devices in their operations. This mitigates the time wastage associated with such activities as well as reducing contamination risks of the powder produced which is of consistent quality in every batch produced.

This rotor is an extraordinary centrifuge that finds its application in multiple industries such as pharmaceuticals food processing and waste treatment Each industry has its share of benefits by employing the cost effective yet efficient auto scraper bottom discharge centrifuge that makes the operation efficient In pharmaceuticals, it ensures product quality by removing solids from liquids In food industry, it also removes water will yield safe products regardless of the conditions There is also the urgent need of centrifuge in a waste water treatment which reduces the quantity of sludge while enhancing productivity It therefore proves to be a versatile device across the sectors.

In the designing of the auto scraper bottom discharge industrial centrifuge the focus is primarily user satisfaction and operational efficiency It has a simple structure so that the personnel operating the machines do not need to oversee processes all the time because majority of the functions are automated This has a very user friendly feature as it means very few new operators can be trained as there is not much to learn In addition the construction of the centrifuge is also built to last and stand up to the test of time even in extreme use conditions. It is also easy to install thus making it possible for the user to employ it to enhance the operational effectiveness.

Jiangsu Huada Centrifuge Co., Ltd., a subsidiary of SCIMEE (stock code: 300425), was established in 1993 in China. We are a leading Chinese centrifuge manufacturer. Over the years, HUADA has always focused on the research and development, production and sales of filtration and separation machinery, and has insisted on building an open and win-win cooperation system to lead the industry with scientific and reasonable technological innovation, win the market with specialized and standardized customer service, guarantee quality with excellent management and provide solutions to the solid-liquid separation problems for each customer with concentrated attention.

25

Sep

25

Sep

25

SepAn auto scraper bottom discharge centrifuge is a specialized machine used to separate solids from liquids in various industrial processes. It features an automated scraping mechanism that continuously removes solid residues from the bowl's bottom, ensuring efficient and uninterrupted operation, particularly in applications with high solid concentrations.

The centrifuge operates by spinning a mixture at high speeds, using centrifugal force to separate solids from liquids. As the solids accumulate at the bottom, the auto scraper mechanism periodically removes them, allowing for continuous discharge while maintaining optimal separation efficiency. This design minimizes downtime and enhances productivity.

Industries such as chemical, pharmaceutical, food processing, and wastewater treatment benefit from auto scraper bottom discharge centrifuges. These machines are ideal for applications involving slurries or pastes, providing effective solid-liquid separation while maintaining product quality and process efficiency in challenging conditions.

Copyright © 2024 Jiangsu Huada Centrifuge Co., Ltd. All Rights Reserved Privacy policy