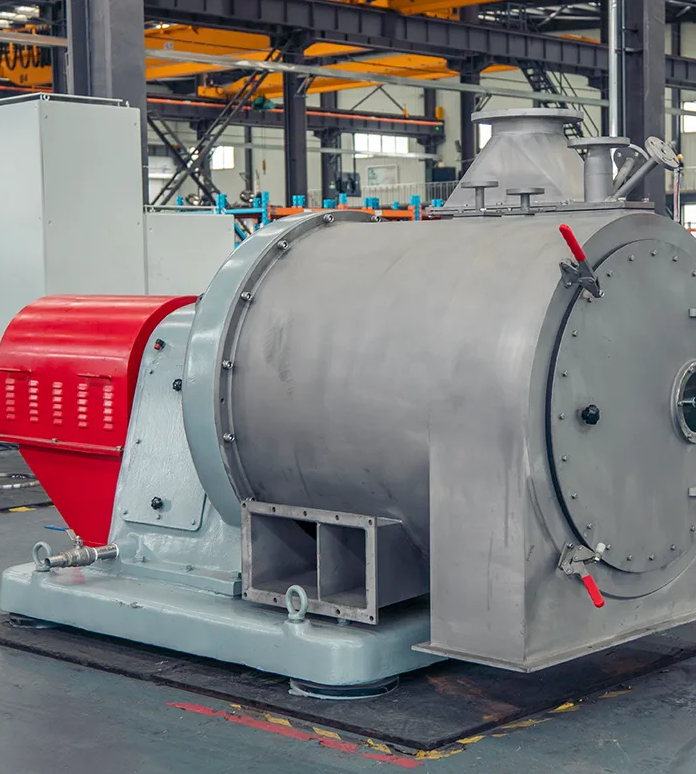

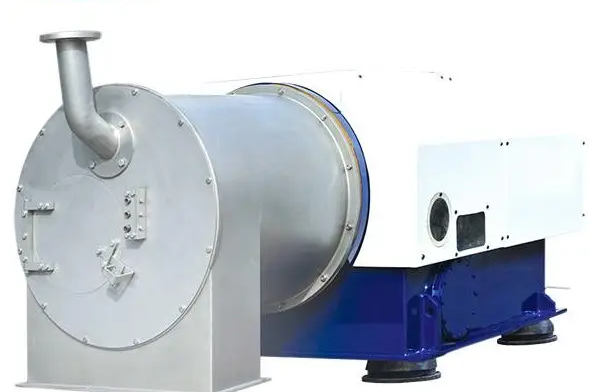

The screen worm centrifuge, which is an evolution of the spin to differentiate separation process, is a very efficient product in a multitude of industrial separation processes. A strong construction is required to prevent breakage or damage to the centrifuge when revolving very aggressive materials. There are many different applications in which this evolution of a centrifuge can be used, but the more advanced temperature, pressure, and environment constraining technologies suggest its area of chemical processing, food and beverage industry, wastewater applications, and so on.

The screen worm centrifuge has been integrated with more aggressive operational characteristics as well. The sopranos control turbine in separator 2 allows alteration of the separating criteria such as rotational speed and the resulting torque. This feature is very beneficial in that it enhances differential efficiency without increasing running costs.

The structure of the centrifuge is kept compact and is easily adaptable to the existing production systems. The touchscreen interface simplifies the way of control and maintenance of the system processes. It has also been verified that the dewatering system designed and executed in this work is deployable with less energy use and waste generation. Businesses are able to use screen worm centrifuge to increase the amount of product obtained from the separation processes required while at the same time decreasing the effects on the environment. This innovative technological approach should be considered in current industrial applications.

When a separation stage becomes necessary in high capacity batch production industries, the screen worm centrifuge presents an efficient and continuous option. This is due to its design that enables it to work on large volumes of loads continuously without rest, It is thus applicable in mining, drug, and food manufacturing. In this device material is being spun at high speed creating a centrifugal force that separates the solid pollutants from the liquid while the internally mounted screw conveys the extracted solids towards the discharge. This enables the flow of materials without the manual loading of materials in between runs which enhances productivity. Since the screen worm centrifuge can be operated continuously without disruption, it allows an industry to reach its set targets more efficiently.

In most industries, solid-liquid separation efficiency is improved with the use of a screen worm centrifuge. Its structural design enables one to work continuously and accurately deals with higher volumes of material. The screen worm centrifuge utilizes centrifugal action to separate liquid from a solid liquid mixture while the internal worm works to ensure that the separated solids are pushed towards the discharge outlet. Thus, this combination helps the centrifuge to stay efficient when processing materials with different densities. The continuous nature means that there is minimal need to come to a complete stop and come back again in order to change direction which means that maximum yields and productivity of processes are achieved. It can be used in a variety of industries including chemical processing, mining and wastewater treatment where separation on a larger scale is required.

There are manufactured screen worm centrifuges with the durability and reliability appropriate for the most demanding industrial environments. Their strong construction permits processing of abrasive materials at elevated temperatures and in adverse environments without performance degradation. The worm mechanism inside the centrifuge is constructed to convey the materials with the minimal risk of clogging the system, hence, promoting long-term service. In addition, the screen part helps improving the quality as particles of only the required size are separated. The nature of ammonium sulfate regulation and performance of the screen worm centrifuge justify the need for uninterrupted process with minimum maintenance as well as low downtimes within industries Marte O in n. profession.

Jiangsu Huada Centrifuge Co., Ltd., a subsidiary of SCIMEE (stock code: 300425), was established in 1993 in China. We are a leading Chinese centrifuge manufacturer. Over the years, HUADA has always focused on the research and development, production and sales of filtration and separation machinery, and has insisted on building an open and win-win cooperation system to lead the industry with scientific and reasonable technological innovation, win the market with specialized and standardized customer service, guarantee quality with excellent management and provide solutions to the solid-liquid separation problems for each customer with concentrated attention.

25

Sep

25

Sep

25

Sep

A screen worm centrifuge is a type of equipment used for separating solid particles from liquids in various industrial processes. Its primary function is to efficiently separate and dewater sludges, pastes, and other viscous materials by utilizing a rotating screw mechanism that pushes the solid particles against a screen, allowing the liquid to escape.

The screen worm centrifuge operates by spinning a cylindrical bowl at high speeds. The feed material enters the centrifuge, where the rotating worm moves the solids towards the discharge end. As the solids are pushed against the screen, liquid passes through, effectively separating the solids from the liquid phase.

Screen worm centrifuges are widely used in industries such as food processing, wastewater treatment, and chemical manufacturing. They play a crucial role in processes like sludge dewatering, juice clarification, and separation of various solids from liquids, enhancing efficiency and product quality.

Copyright © 2024 Jiangsu Huada Centrifuge Co., Ltd. All Rights Reserved Privacy policy